Engine cooling - Part I.

Engine cooling

Heat dissipation, story first

Automotive Engine Cooling System (PD) Essential Parts

Namely, the propulsion machine of a car (whether it is a petrol or diesel engine) is in fact a thermal engine, ie one that converts thermal energy into mechanical work. But even the most advanced internal combustion engines we know today are not very efficient in terms of efficiency, which is the main reason for the need for a cooling system. In particular, gasoline engines today have an efficiency of only 25 to 30%. This means that as much as 70 to 75% of the energy in fuel (gasoline) is converted into (excess) heat, not useful work. Furthermore, about half of the heat thus generated leaves the engine through the exhaust system, and half is taken up by the engine cooling system. Let us also mention that diesel engines have higher efficiency than petrol engines and are so modern Common Rail drive motors have an efficiency of about 40%.

If we take into account that temperatures of around 2200 ° C develop inside the cylinder when the mixture of fuel and air burns, it is clear that without some cooling system, the engine would soon begin to disintegrate, and its parts would deform or even melt. As the cylinder walls themselves must not be heated to more than 260 °, when the oil decomposes and its lubricating ability drops drastically, the heat generated must be somehow dissipated. The heat dissipation (cooling) in most of today's car engines is taken care of by the coolant. On average, this method removes about 1/3 of the total amount of heat (thermal energy) generated in the combustion chamber. But in addition to cooling the cylinders and other parts of the car engine, the cooling system has two other functions. The first in terms of importance is certainly the one in which this system takes care of maintaining the correct operating temperature of the engine, while the second task is to enable the heating of the passenger compartment.

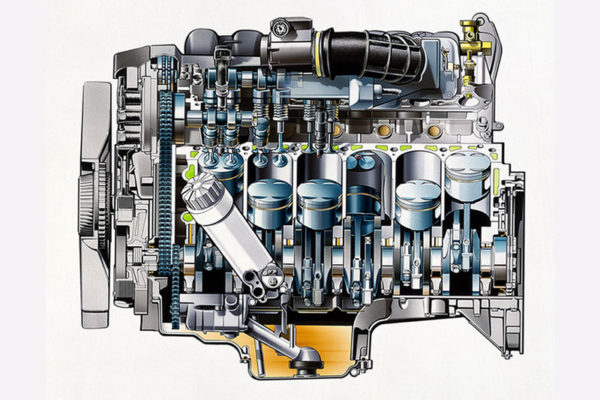

The so-called 'water pockets' or coolant channels are painted green (Daimler AG)

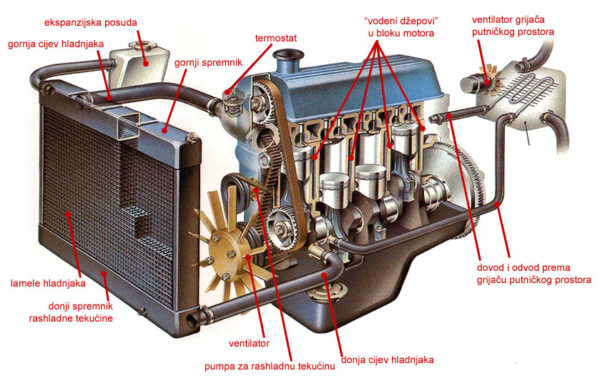

Cooling system, part by part

The basic parts of the cooling system in water-cooled engines (common term for coolant-cooled engines) are: water pockets in the block and cylinder head, water pump (coolant), thermostat, radiator and fan. Well, let's start in order. The so-called "Water pockets" are actually cavities in the engine block (remember the story of how the engine block is made) in the form of some kind of pockets, and they are intended for the flow of coolant so that it can come into contact and thus cool the outside of the cylinder walls. We find the same cooling pockets in the cylinder head (in both cases they are openings of round but irregular cross-sections that we see on the upper part of the block and the lower head), and the purpose of this is to remove heat from the outer walls of the combustion chamber.

In the case of a wet cylinder liner, the coolant in the engine block does not flow through the pockets, but represents the space between the inner walls of the block and the outer walls of the cylinder liner.

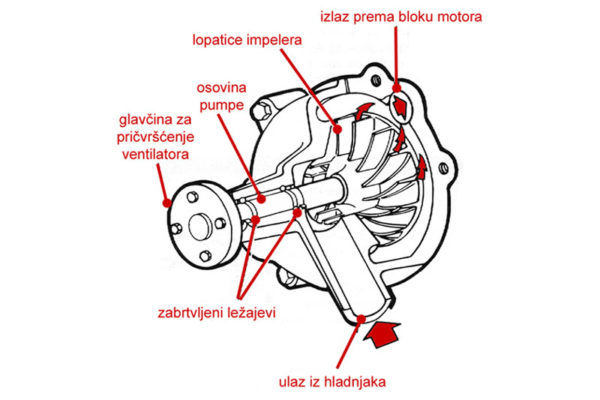

Coolant pump

The second part of the story about the cooling system and its basic parts is the coolant pump. Most liquid-cooled motors are centrifugal pumps that use an impeller (a rotor with many blades to start the fluid flow). Coolant pumps are usually driven by a V-belt that comes from a pulley located on the crankshaft outlet, but some pumps are also driven by a gear system. At the highest speed, the coolant pump can run up to 28.500 liters of water in one hour, when the thermostat is open. In their rotation, the impeller blades "pull" the coolant from the bottom of the radiator and force it through the engine (pockets) and back into the upper part of the radiator. The shaft of the water pump is placed in sealed bearings and does not need additional lubrication.

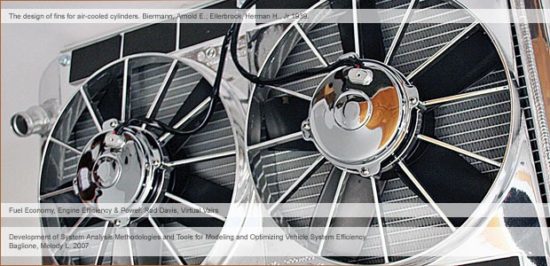

Classic Metal and Plastic Electric Fan Cooler Fan (Speedway Motors, Inc.) Classic Metal and Plastic Electric Fan Cooler Fan (Speedway Motors, Inc.)

The refrigerator fan is not a friend of your fingers, is it?

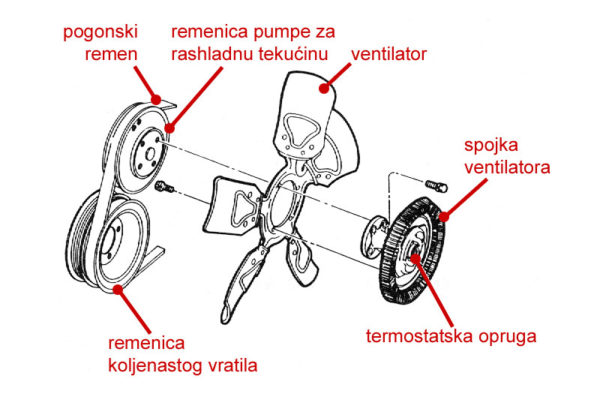

At higher vehicle speeds, the air flow that reaches the radiator through the bonnet (or inlets) and passes through its grille structure is sufficient to cool the coolant. But when the car is standing or moving slowly, it is necessary to increase the air flow through the radiator. That is why, next to the water-cooled engine coolers, we see a fan. Fans of car engines differ in the way they are driven, so we know fans driven by a pulley or those driven by an electric motor. The first ones are driven by the water pump pulley, since they are (immovably) attached to it. The faster the crankshaft rotates, the faster the coolant pump and the fan will rotate. Such fans are more common with larger engines that are typically mounted longitudinally in rear-wheel drive cars.

Variable speed fan equipped with thermostatic clutch

One of the versions of the mechanically driven fan is the fan that has a built-in thermostatic coupling that reacts to the temperature of the air flowing through the cooler. Thus, switching off reduces the motor load and the noise produced by the fan blades, while the fan starts as needed. However, in most of today's cars, and especially those with a transversely mounted engine and front-wheel drive, we find a fan driven by an electric motor. The advantage of such a fan is that its operation takes less motor power, and it is possible to turn it on more precisely (at 93 ° C).

A significant warning regarding car radiator fans is that under no circumstances should the fan blades be touched while the engine is running. The engine temperature rises the fastest when there is no airflow through the cooler (standing still) and the sudden start of the fan can have very serious consequences for the curious fingers! This warning should be taken particularly seriously with engines equipped with air conditioning. Namely, their condenser requires an almost constant supply of strong air current, and in such cars the fan is almost always in motion (or at least while the air conditioner is running).

author: AUTONET.HR

Recommendation of similar texts:

Hi there, I am Mladen and I am an auto enthusiast. I started this blog years ago to help like minded people share information about latest cars, car servicing ideas, used car info, exotic cars, and auto technology. You will find helpful articles and videos on a wide variety of cars - Audi, Mercedes, Toyota, Porsche, Volvo, BMW and much more. Ping us if you have anything cool to share on latest cars or on how to make older cars more efficient, or just want to say hi!