Engine cooling - Part II

Engine cooling

Heat dissipation, story two

Car Engine Cooler (Jeep / Chrysler Group)

That is why, in addition to the already known parts, such as the coolant pump, fan or ducts, we will be explaining how heat is transferred to the environment, maintaining a constant (or desired) engine temperature, and other things that the previous chapter did not cover. .

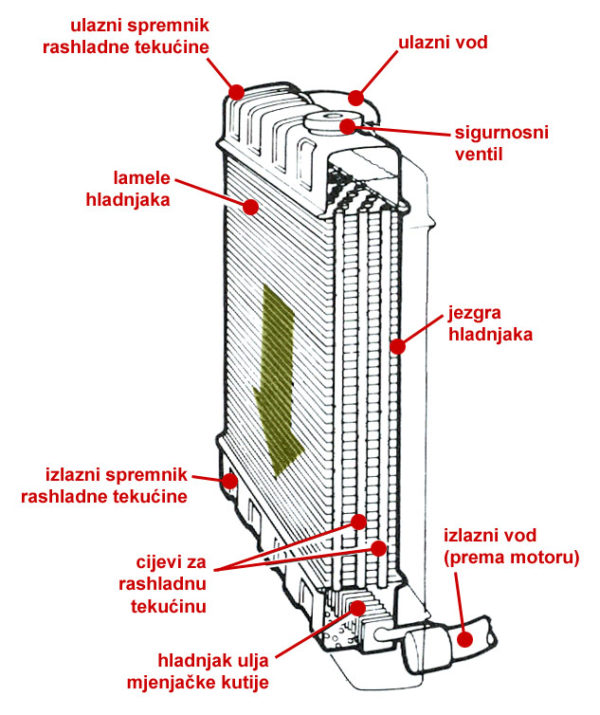

Main Parts of a Car Radiator with Transmission Oil Cooler (Chrysler Group)

Car engine cooler

A refrigerator or heat exchanger is actually the same as your home radiator. Its role is to remove heat from the coolant, which is achieved through the flow of air.

The refrigerator consists of four basic parts, namely: inlet and outlet tanks, coolant passage pipes and slats. The inlet tank is the chamber at the top of the radiator into which the heated coolant from the engine comes. From it, it flows through pipes that are surrounded by blades. Lamellae are thin metal strips that are attached to pipes that are heated by a coolant and increase the surface area of the fluid. Likewise, the surface through which fan-driven air or simply moving the vehicle flows increases. This flow of air removes heat from the slats, and indirectly from the pipes and thus the cold coolant, or. antifreeze (engine coolers with built-in air conditioners typically have a density of 14 blades per 5 cm).

Car Heat Exchangers (Saab Automobile AB)

At the bottom of the refrigerator there is an outlet tank in which coolant is collected from where it, driven by the pump, flows back into the openings of the block and head. Pipes with radiator blades are commonly referred to as the radiator core, which in most cars today is mostly made of aluminum. The inlets and outlets of today's refrigerators are made of plastic, but they are also used in metal, and it should be noted that all these parts (the entire refrigerator) were once made of copper.

Depending on the position of the inlet and outlet tanks, we distinguish between the coolers of the vertical and horizontal coolant flow. In the vertical cooler, the inlet tank is located at the top and the outlet tank at the bottom, while in the horizontal cooler they are left and right. Most modern heat sinks are precisely these last, horizontal, structures that reduce overall height and allow the heat sink to be positioned under more laid bonnets.

W16 engine from Veyron EB 16.4 (Bugatti Automobiles SAS)

Probably the absolute record holder by refrigerator count is currently the Bugatti Veyron EB 16.4. Namely, this car is equipped with as many as 10 coolers, of which: 3 are intended for engine coolant, 3 are intercoolers (intercoolers) precharging system, 1 is the air conditioning condenser, 1 radiator cools the transmission oil, 1 is the differential oil cooler, and one radiator cools the engine oil. Let's also say that the EB 16.4 has two separate coolant circuits, one for cooling the engine with a volume of 40 liters of coolant and one that connects the intercoolers, which has a volume of 15 liters.

Thermostat (Mitsubishi Motors)

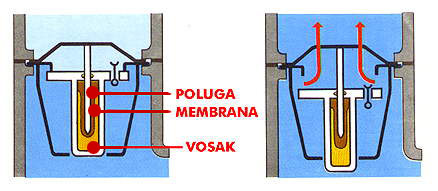

The thermostat is in fact a control valve controlled by the coolant temperature. Its task is to help the engine warm up faster, which is achieved by redirecting the flow of coolant. In fact, it is clear that the coolant in the normal operation of the (heated) engine flows through the cooling openings ("pockets") of the block and the head and then into the radiator and back again, assisted by the pump. When the engine is cold, the thermostat is closed so that the coolant (forced by the pump) flows only through the block and the head. When the liquid is heated enough, the thermostat opens and the coolant then begins to circulate throughout the system, so it begins to cool in the refrigerator.

Basic parts of a 'wax thermostat'. The thermostat is closed on the left and open on the right

Electrically operated thermostat with connection for heating element (BMW AG)

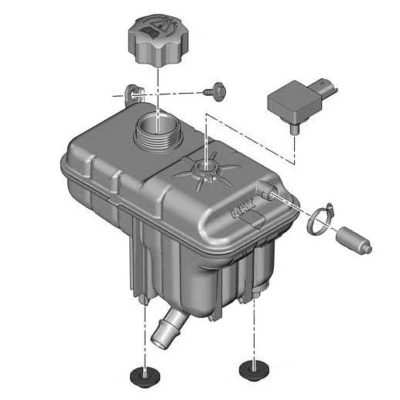

Expansion tank for coolant (Automobiles Citroën)

Expansion vessel of cooling system

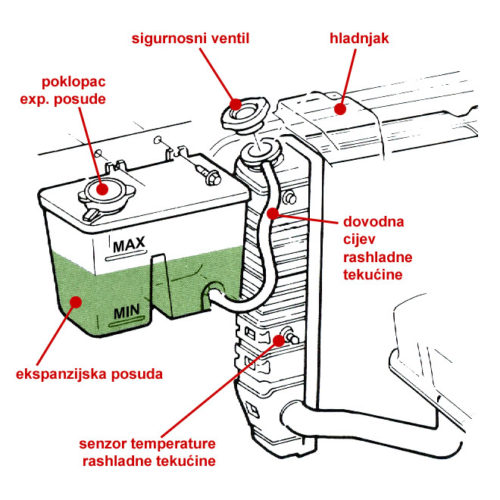

The expansion vessel of a cooling system is usually that large transparent plastic box into which (in most) the engine is filled with coolant. There are also some "MIN" and "MAX" markings on this tank, between which there should be a liquid level when the engine is cold. This way, after all, we always know if there is enough coolant in the engine (after all, the cooling system of a car engine with an expansion tank is a so-called "closed system", at least in theory, the fluid should never be missing). We know that the liquid stretches when heated, ie. to increase their volume as well as the wax in our thermostat. Thus, the coolant passes through the increase in volume, ie. antifreeze.

As it is important for proper and quality engine cooling that the complete cooling system (cooler, supply and exhaust pipes, "pockets" in the block and head) is completely filled with liquid, we see that when heating, the problem of excess coolant can occur. Then an expansion vessel enters the "game" into which the excess coolant is poured in order to make enough space for it in the cooling system.

Expansion vessel and cooling system parts (Ford Motor Company)

When the engine is turned off and the coolant in it cools, a vacuum is created in the cooling system that "pulls" the coolant back from the expansion tank. In addition to the role of absorbing excess coolant, the expansion vessel also helps to eliminate air bubbles that accumulate in the system, which increases its filling with liquid, and thus the cooling efficiency.

When we talk about the expansion vessel, it is necessary to mention something else. Namely, as the volume of the cooling liquid increases with heating, the pressure in the cooling system also increases. At the same time, the boiling point of the coolant increases with increasing pressure. Namely, we know that the boiling point of water at atmospheric pressure is at 100 ° C.

By increasing the pressure by 1 bar above atmospheric pressure, the boiling point of water rises to about 130 ° C. Of course, the coolant itself jumps into the "story", which in principle has a boiling point slightly higher than ordinary water. Finally, the cooling system is also equipped with an overpressure protection valve. It usually opens between 0,6 and 1,0 bar overpressure, depending on the engine design.

Antifreeze in the radiator orifice (PD)

Coolant or our precious antifreeze

Engine coolant is actually a mixture of distilled water and a special liquid called antifreeze, which is, in turn, a liquid for lowering the freezing point of the coolant. The main component of antifreeze is divalent alcohol, ethylene glycol, thanks to which it is possible to lower the freezing point of the coolant and thus enable the use of vehicles in cold weather conditions. Namely, as water freezes at 0 ° C, in a cold climate, the cooling system of a car engine would quickly become unusable because freezing would stop the flow of coolant. Also, since the frozen water has about 9% more volume than the liquid, freezing the coolant would cause the engine parts, radiators, etc. to burst.

The usual ratio of antifreeze and distilled water in the coolant is 50: 50 (depending on the type of antifreeze), which is usually enough to reduce icing to -37 ° C. Sometimes, in more extreme climatic conditions, a 70% concentration of antifreeze in the coolant is used, which reduces icing to -64 ° C. In addition, 50% antifreeze raises the boiling point of the coolant to 108 ° C, which allows to achieve higher pressure in the cooling system and thus the cooling effect of the engine.

While lowering the freezing point is the primary role of antifreeze, the special additives contained in it have an additional role. Thus, in addition to ethylene glycol, antifreeze often contains chemicals to prevent corrosion and those to prevent foam. That is why it is necessary to use antifreeze (ie its mixture with distilled water) in the cooling systems of the vehicle always and even if you live in a climate where the temperature never falls below the freezing point of water. Finally, let's say that the antifreeze is usually painted to make it easier to notice a possible coolant leak.

Air Cooled Boxer Motor (BMW AG)

The end of the story that penguins probably enjoyed the most was related to air-cooled engines. Often seen on motorcycles, these engines are recognizable by the ribs surrounding the cylinder. The cooling fins here act in the same way as the radiator blades, in that they are much larger and, in most engines, poured into the block unit. These ribs show different lengths and a narrowing shape towards the top.

First, there is a reason that for cooling the more loaded parts of the engine, it is necessary to put longer ribs. As for the sharpness, the "game" is that the heat tends to spread from a larger to a smaller cross section, and the ribs of the air-cooled engine are thinner at the farthest point. As a rule, air cooling of automobile engines is assisted by a fan that works constantly in order to enable the conduction of sufficient air flow.

Recommendation of similar texts:

Hi there, I am Mladen and I am an auto enthusiast. I started this blog years ago to help like minded people share information about latest cars, car servicing ideas, used car info, exotic cars, and auto technology. You will find helpful articles and videos on a wide variety of cars - Audi, Mercedes, Toyota, Porsche, Volvo, BMW and much more. Ping us if you have anything cool to share on latest cars or on how to make older cars more efficient, or just want to say hi!

Hello i have a lagoon wagon 1.8 engine 97, year. A year ago did a great service and since then the temperature in the engine rises to the maximum. Masters say I start the air conditioner that the fan can be turned on and then lower the hand and that's it says the thermostat is not. I ask you what that could be. I'm already crazy I don't know who to turn to for this problem.