Piezo injectors - Common rail system - how it works

Piezo injectors

The development of modern diesel engines is now determined by the limits of toxic exhaust.

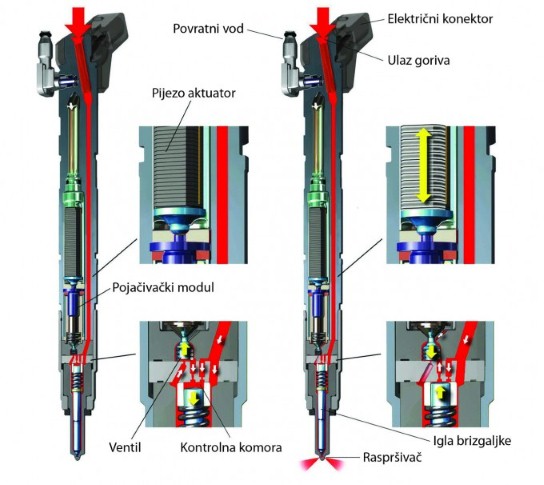

The injector is a critical part of the modern injection system. There are two types of injectors: electromagnetic injectors, which allow for injection of 5 parts fuel and piezoelectric injectors, in which the dose can split up to 7 parts. Solenoid-controlled injectors have non-return valves and springs, which causes inertia in its operation. Piezoelectric injectors can be in versions without any springs and non-return valves. Reducing the number and weight of moving parts (up to 75%) reduces the inertia of the injector and allows for greater accuracy and speed of fuel delivery.

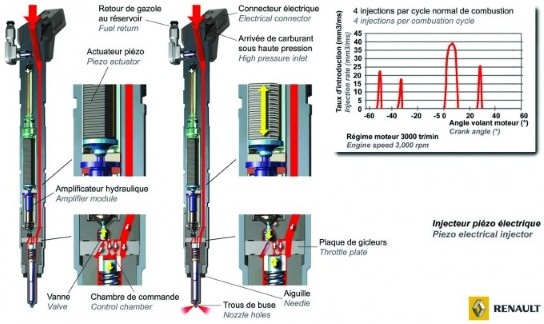

Because the injection is fully electronically controlled, multiple injections can be made and high injection pressures can reduce exhaust emissions and fuel consumption, with excellent driving performance and low noise.

The role of injectors is to inject a certain amount of fuel very precisely into the chamber. To increase precision, the operating pressure is increased to 2000 bar, and the mechanism that drives them is based on a piezo system that provides high speed and accuracy. in case they are exposed to electrical voltage, they have mechanical displacement. In a piezo injector, a multi-layer ceramic element is used as a so-called piezo pole of interconnected elements.

The injector consists of three parts, the injector servo valve, the piezo actuator and the compensation element, which are arranged in a row one after the other. The sand activator directly pushes the needle of the injector, so that very precise injection is achieved without stopping. The thermal expansion compensator of the spreader body of the injector and the piezo ceramic, which operates on a hydraulic principle, is mounted above the piezo actuator, thus providing fuel flow.

The injector opening characteristics are formed so that the maximum stroke is reached in about 200 milliseconds. As a rule, switching times can be shorter and not limited to 200 milliseconds by piezo ceramic dynamics. However, in this case, more power is required in the actuator electronics without noticeable improvement in the combustion process. Closing time from maximum stroke is also about 200 milliseconds. A partial stroke can also be achieved when needed.

Piezo injectors

Fuel injection diagram in cylinder

Thanks to such electronic regulation it is possible to vary the start, duration and flow of injection, and thus the amount of fuel injected. This gives great precision in terms of both injection flow and reproducibility in all successive duty cycles. For variable engine modes, a very short reaction time that is four times shorter than with an electromagnetic injector is important. This provides the optimum injection flow for all operating modes and loads in terms of engine efficiency and exhaust composition.

Piezo injectors

Each syringe is precisely calibrated

Breeze is crucial - Piezo injectors

Peso injection molding techniques are used to achieve speed and precision. Experience so far has shown that a piezo injector can reduce exhaust emissions by up to 20 percent or increase power by 5 to 7 percent. Bosses engineers say the life of the injectors is between 150 and 250 thousand kilometers, when their performance is significantly poor. When changing, it is advisable to change all the injectors.

Recommendation of similar texts:

Hi there, I am Mladen and I am an auto enthusiast. I started this blog years ago to help like minded people share information about latest cars, car servicing ideas, used car info, exotic cars, and auto technology. You will find helpful articles and videos on a wide variety of cars - Audi, Mercedes, Toyota, Porsche, Volvo, BMW and much more. Ping us if you have anything cool to share on latest cars or on how to make older cars more efficient, or just want to say hi!