Manual transmission - how a manual transmission works

Manual transmission

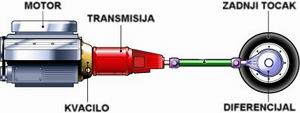

One of the most important parts, that is, the systems of each car, is certainly its transmission. Every car must have its own transmission, because the concept of proper engine operation is based on the optimum utilization of its power, as well as the proper transfer of real engine power to the driving wheels.

You know for yourself what would happen if any modern car had only one so-called. "Speed", that is, when the power and rpm of the engine would be directly transmitted to the differential, that is, the wheels.

Same thing as with, for example, a Pony bike. This bike transfers the pedal to a chain to the rear wheel axle, or to one gear on that axle. This gear is usually of some medium size, thus compromising more efficient starting and high speed. Namely, the "pony" can be started nicely and quickly, but in order to allow at least approximately high speed, for example a mauntin-bike it would be necessary to approach extremely fast pedal rotation, which is often very difficult and impossible. That's why modern bikes today have several gears on both the axle and pedals, allowing for a very versatile ride - easy steep slopes using a lower gear, or larger gear on the axle, and vice versa for fast, straight and downhill journeys.

Totally identical, but much more complex is the principle with cars. Many are probably wondering why we have so many gears on the bike today (18 and over) and only 4-6 on the car? The answer is very clear - the car consumes fuel and it does not get tired and can thus be exploited at the expense of higher fuel consumption. On the other hand, the transmission to the 'fairy tale' is designed to minimize the effort that a person will put into starting the same - thus, more gears make driving easier.

We can also add heavy trucks, buses and similar vehicles to this story. We all know that the aforementioned gearboxes have much more gear than a classic car, and this is mainly because of the specific needs of those vehicles. It counts for extreme situations like starting one e.g. a big truck full of heavy material - uphill. In this case, we need first and foremost exceptional power and then adaptive transmission - the first speed of this truck is specially tuned to make it easier to handle situations like this. As with a bicycle, the first gear in the transmission system of such a truck is extremely large and can be easily rotated, but at the same time requiring a high engine speed. This example can easily be explained by the fact that, on a straight road, the truck always starts from a resting place from a second, sometimes a third speed. Quite simply, the former is only used in special cases and has no usable value in normal driving.

So the very concept of manual transmission in serial cars is very clear and simple. Generally, in this system, we have several gears of different sizes that are connected to the wheels via differentials, which in turn, on the other hand, are connected to other gears driven by the engine. Simple as that.

Yes, the concept is really the same, but in practice, there are millions of details and features that complicate the whole process. Like how to put a transmission in reverse? For now, we know that the car is being started based on the rpm of the motors being transmitted to the drive wheels. How do you reverse the direction of rotation of these engine RPMs to allow the car to move back and forth? You'll see later, very easily ... Now let's start with some basic things.

Each engine of each car operates on the same principle - it allows rotation to achieve a certain number of revolutions per minute. Each engine individually has its own rotation interval in which it rotates safely. You can easily see this by looking at the dashboard on the instrument panel. Stronger machines have longer intervals, while they are significantly reduced in diesel engines, which explains the fact that a six-speed manual gearbox is most commonly encountered in stronger diesel engines. Quite simply, their engine enters "dangerous rpm" (red zone) as early as 4000 rpm and thus requires more gears to make greater use of the engine's capabilities. A large number of speeds allows them a very fast start, but also low fuel consumption.

There is immediately another side to the story. If anyone used to drive Opel Cadet in the GSI version, he could see a graphically displayed rotometer on his LCD board. On the transparency side, it was nothing special, but it helps us a lot here in our story. Namely, you have noticed for sure that this rotometer is irregular in shape - that is, it is made in the form of some curve coordinate system, which reads the current engine speed. This curve rises very rapidly to around 5-5.500 rpm, then drops sharply to around 7.000. This curve really represents a curve from a rectangular coordinate system, the one by which the engine torque, that is, its power in hp, is represented. So the power rises from 1.000 rpm to the point where the curve reaches its maximum. Then the engine uses all its available power, ie. working to its maximum.

After 5.500 rpm (where the maximum is located), it enters the red zone slightly, the engine overloads and the power decreases. After some driving time in the red zone, the engine will definitely explode! The goal of transmission, among other things, is to ensure that the engine never turns in the red zone, ensuring safe operation with maximum safe use of its capabilities through these few specially designed "speeds".

Before we get to know the basic parts of every manual transmission, there is one more thing to explain. If you've ever read a serious car magazine / catalog, you could see some transmission data for each of the specified speeds that car has.

So those are the digits in the form of scale - 2,399: 1; 1,081: 1; 0,887: 1, etc. What it means? This is actually the ratio between engine speed and wheel speed, that is, gears in some gear. Take for example these three data mentioned above.

In the first case, we have a ratio of 2,399: 1. On the left side of this scale is always the engine speed, while the unit on the right represents the speed of the transmission output to the differential (practically, the speed of the drive wheels). So at 2399 engine rpm, the transmission output will reverse 1000 times over the same time period. Considering that this ratio is significant in terms of engine speed (make 1399 more rpm), we come to the conclusion that this ratio is characteristic of the first gear of a serial passenger car.

The second example mentioned above could be some third or fourth gear, while the third example could certainly be the last in that transmission - the fifth or possibly the sixth, given the lower engine speed compared to the outputs of the outputs, wheels.

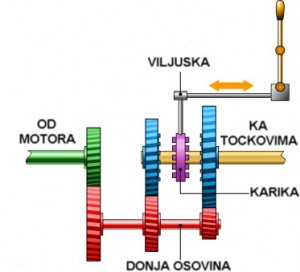

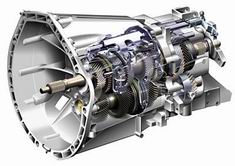

We will first present a concrete explanation of how manual transmission works on a very simple example of two-stage transmission. This type of transmission is also shown in the figure accompanying this passage.

So, from the picture we can see several parts of this simple system. Let's go from left to right. The first in the picture is a green colored gear that rotates around its axis, which in this case is a continuation or output from the engine of the vehicle. So the engine makes a certain number of turns, which is transmitted through that green shaft to the green gear, and therefore, it rotates at the same speed and in the same direction as the engine.

Next we have a red gear that continues to green. They are always tied and always depend on the speed of the engine itself. This gear and the connection between the motor output and the transmission input enable the lower transmission shaft ('layshaft') to be driven, which, in addition to the red gear, contains a number of them.

The number of gears remaining is equal to the number of gears (“speed”) of the car. What is important to remember here is that this lower (red) shaft rotates at the same speed, or always at the same speed as the engine speed. The connection between red and blue gears is most easily explained by the example from the beginning of this text - by bicycle.

In our case presented here, we have a red gear, which is a bicycle pedal gear, and a blue gear, which is a gear on the rear axle of the bike. By turning the pedals, we in real time influence the movement of the first gear, which is chain-linked to one of those gears on the rear axle.

In our example, the red gear is the one driven by the engine, while the blue ones are tied to the shaft, which is the output of the transmission system and is tied to the differential, or the drive wheels themselves! Of course, the picture shows that all these gears (one red and blue for each gear) are different sizes and that if they were all connected (as pictured) they would not be synchronized at all and this would cause safely until the shaft or one of the gears is cracked.

Now - it's true that all red and blue gears are tied, but unlike the red ones, the blue ones rotate freely around their axis, that is, they are not attached to the shaft on which they are located, they have small bearings that allow them to rotate freely! So in our case both blue gears will rotate around their axis, the gums faster than the left ones.

How do we now tie the axle that is the only one in our picture that is still and that actually represents the output and the transmission link with the wheels? Easy - with S ... Here comes the purple section, a special kind of circular link that is tied to a gearbox by a special fork. This link, unlike blue gears, is fixed to the output shaft!

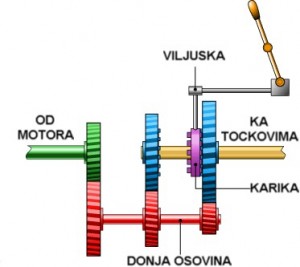

By moving the selector lever forward (by inserting into first gear), we are actually moving this link backwards. It then attaches to the blue gear (XNUMXst gear) by inserting certain projections on the side of the link into the recesses on the blue gear. Thus, that link and a particular gear are tied together and, since this first link is directly connected to the output shaft, they rotate. Thus they indirectly bind green, red, and finally a certain blue gear.

In the second image in this passage, we can see our two-speed transmission in the first gear, while the top image shows the ler position. This is really the simplest representation of manual transmission, and one question immediately arises: how is it possible to connect the link (the purple part in the picture) to the blue gear, if we said earlier that the blue moves at the same pace as the engine itself?

How can it be so easy to make a gear shift when everything is in motion ?! Well, it's not possible. This is where the very important role of the clutch comes into play. The clutch separately separates the operation of the motor and the shaft leading to the transmission system (green shaft in the figure).

This stops the rotation of all the gears inside the system for a moment, in order to seamlessly connect the link and gear of a certain gear. By releasing the clutch pedal, the operation of the engine and the transmission are re-coupled, and thus the rotation is also transmitted to the output shaft of the transmission via a specific (blue) gear.

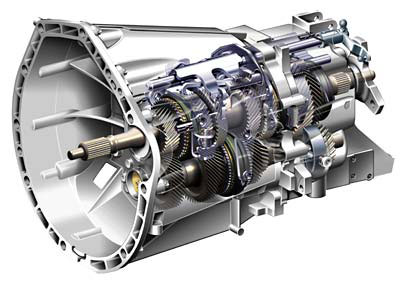

OK, it was easy to explain all this with the example of a manual transmission with only two gears, but what does it look like with today, most often, five-speed transmissions? The principle is essentially the same, except that we now have more gears, which pulls more gears, we also have special gears for reverse, as well as more forks tied to the gear lever itself.

In the two-gear example, we only had three gear lever positions - LER (neutral), when the lever position is in the middle as well as the linkage position itself (between the first and second gears blue); then the FIRST gear, when moving the lever forward, move the link backwards, thus connecting it to the gear, and the second gear, when moving the lever back. It is, therefore, a classic line transmission.

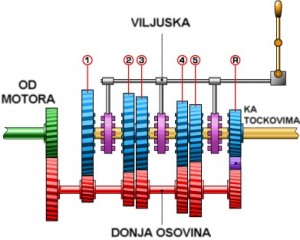

We all know that today we have H - type transmissions on production cars. It is such a more complex concept to successfully fit all 4, 5 and 6 gears, respectively. The five-speed transmission contains 5 blue gears + reverse, which also requires 3 links (one between the first and second gears, third and fourth gears, fifth gear and reverse) as well as 3 forks. We can also see this in the attached picture, which shows us the five-speed transmission system.

Moving the lever to the left will activate the first link, when choosing whether to put it in first or second gear. Returning the lever to the center position will activate the second link, which refers to the third and fourth degrees, while moving the lever to the rightmost position, we put the last, third link when choosing between the highest, fifth gear and reverse. There are several modalities of this H-pattern, where the reverse can be at the first or second "speed". So the very principle of how this system works is even simple.

The complexity here is the connection, ie synchronization between certain gears, that is, generally between the engine and the transmission system. That is why the above-mentioned relations between the engine rotation speed and the transmission output are important. In the pictures themselves, we can see the difference in size between the individual gears - the (blue) gear of the first gear is extremely large, while its (red) gear-starter is extremely small in diameter. This allows a large gap in the relationship between engine rotation speed and transmission and makes it easier to start the car from a place, but does not promise high speed.

By this very logic, we find that as gears increase, the (blue) gears on the transmission output decrease and the actuators (red) increase. There are many details in this system that need to be taken into account in the construction, such as special synchronizers that help more easily connect the transmission links to a specific gear with the help of friction between them. They provide a minimum amount of gearshift speed, but we won't talk about them specifically now…

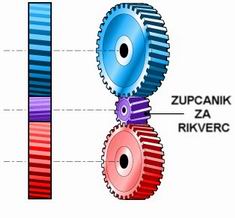

I also owe you the principle of reverse. As I said at the beginning of the text, the principle of walking backwards is very simple. The reverse works like any other normal gear - so it has its own (blue) gear that rotates freely around its axis and is connected by a driving (red) gear. The only difference with this system is the presence of another extra gear, very small in size, located between blue and red (pictured). By logic, that little gear changes the direction of the shaft of the transmission output shaft, thus providing reverse motion. From here we can see that the car, with the handle in the reverse position, must always be idle! If the car is moving in the back, pressing the clutch pedal can turn you into reverse, but after the pedal is released, serious wear and tear (maybe an explosion!) And certain links and gears will occur because the output shaft and gears will move in the opposite direction.

This was, on the whole, the most basic thing to say about a manual transmission system. It should be borne in mind that every system of such transmission differs, not only from manufacturer to manufacturer, but also to car models. Because, as we said before, there are always different ratios of engine speed and shaft to differential. Nevertheless, the idea and principle are always the same and always repeated.

Retrieved from: www.automobilizam.net

Recommendation of similar texts:

Hi there, I am Mladen and I am an auto enthusiast. I started this blog years ago to help like minded people share information about latest cars, car servicing ideas, used car info, exotic cars, and auto technology. You will find helpful articles and videos on a wide variety of cars - Audi, Mercedes, Toyota, Porsche, Volvo, BMW and much more. Ping us if you have anything cool to share on latest cars or on how to make older cars more efficient, or just want to say hi!