Electronic ignition system for petrol engines

Electronic ignition system

Meaning the same, simpler version

In car parts where mechanical components have been replaced over time, electronics generally offer a higher level of reliability for some systems (this is relative, but if we talk about mechanical contacts that wear out over time, the theory gets some justification). Also, there is a simpler construction, lower price (resulting from the above) and lower weight of the entire system. After all, if you replace a massive, metal ignition distributor with a "black small box" that contains only a couple of electronic components, the savings in mass will not be negligible.

Coil of Freelander V6 Engine (Land Rover)

And let's not forget, considering that we are talking about high voltage and some sparks which, in the end, ignite the mixture of fuel and air, our story still revolves exclusively around the petrol (Otto) engine. Fans of diesel engines have "pulled out" this time as well, but although they carry slightly fewer components under the hood, the higher loads that diesel engines can withstand (of course, the law of demand is also important) are the root cause of the slightly higher price. powered cars.

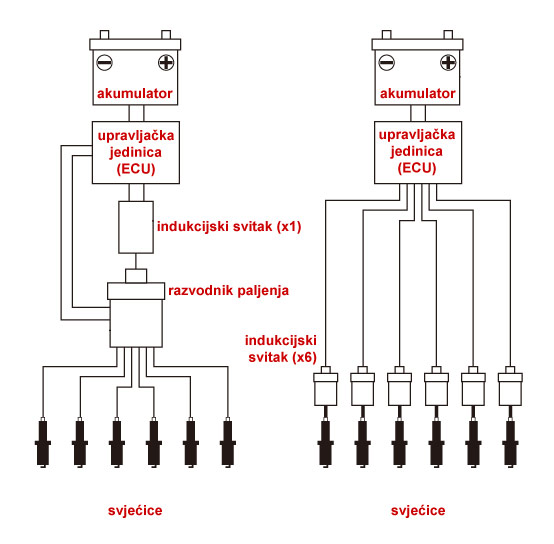

Comparison - Electronic ignition system with distributor and DIS system

Most owners of today's cars will not, when peeking under the hood, come across anything that would be similar to the previously described ignition distributor. It is about the fact that modern engines, thanks primarily to electronic systems, have a much simpler ignition solution. In modern cars (this "modern" applies to most vehicles younger than the 1980s) is a set of large induction coil (coil) and mechanical ignition distributor, together with its vacuum (or whatever, depending on the version) ignition timing system , replaced a set of several electronic components.

Electronic ignition

Today's ignition systems, as a rule, do not distribute high voltage current (as with a mechanical distributor), but the function of voltage distribution takes place in the primary circuit (low voltage). The low-voltage pulse is thus brought to the individual induction (high-voltage) coils, which are arranged one for each spark plug or one for each two cylinders.

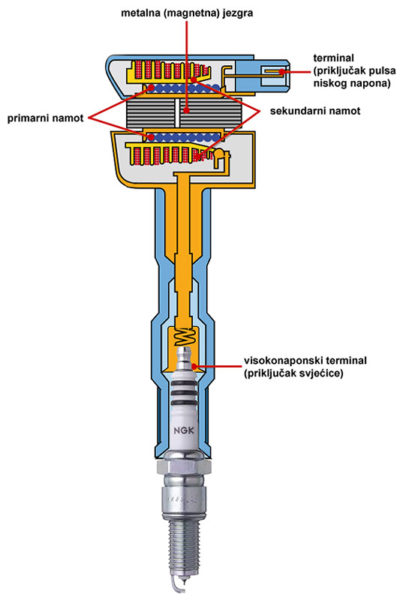

DIS System Coil Cross section (NGK)

The coils can be arranged in several ways. In the case of the construction "one coil - one spark plug" or DIS - Direct Ignition System, are usually placed next to their spark plug (very close or directly connected to the spark plug). However, they are more common in kits that change the whole coil in case of failure, or, depending on the construction, it is possible to replace each individual coil.

An even more advanced direct ignition system used today in large-series cars is the CDI (Capacitor Discharge Ignition) developed by General Motors brand Saab. One small coil with a capacitor mounted directly on the spark plug is used here. The role of a capacitor is to store a small amount of electric charge for a short time before it is delivered to the primary part. In this case, the voltage increase is realized in two steps: the first raises the battery voltage from 12 to about 400 V, while before delivery to the spark plug, this voltage increases to 40.000 V. This system is characterized by reliable operation and high durability.

Certainly, it should be noted that in today's electronic world there is no more mechanical drive of the ignition distributor, vacuum compensator and the like. The whole ignition story is thus monitored by an electronic unit that receives information from a variety of sensors, such as crankshaft position, engine speed (engine speed, etc.).

Electronic control unit CDI ignition system (left) and coil with associated connector (M&W Ignitions)

And, how did we get to what we're talking about?

It is clear that the car designers did not decide "overnight" to replace the mechanical ignition distributors with electronic systems. The story went gradually, and we believe that many readers will remember the so-called "Conversion kits" thanks to which it was possible to convert classic mechanical ignition distributors into transistor ones.

The first step forward, compared to conventional ignition distributor systems, was contact transistor ignition. In that case, a transistor was added to the entire ignition distributor construction, which is in charge of interrupting the primary circuit. Thus, a current of 0,05 to 0,2 A passes through the circuit breaker ("platinum"), unlike the classic system where the circuit breaker is exposed to a power of 4 A. The effect of contact transistor ignition is clear and is reduced to less wear of the circuit breaker contacts. now exposed to currents of lesser strength.

Contactless transistor ignition was the next step in the development of this story, and in it the switch was completely thrown out of the "game", and its role was taken over by the induction ignition initiation system. However, no matter how much progress such solutions have offered, the problem remains numerous "tails of the past". Thus, e.g. both transistor ignition modes still use a system to change the ignition timing, either vacuum or centrifugal. Mechanical regulators, of course, are not able to provide a level of precision (theoretical and reliability) of electronic systems, so these transitional, slightly more advanced ignition distributors have been completely replaced by electronic systems with small, individual coils.

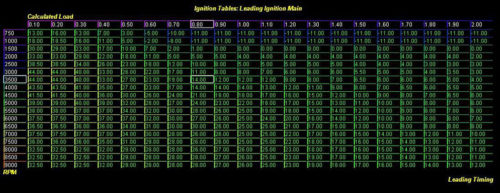

Ignition Map of a Mazda Renesis Engine with Turbine (rx8club.com)

Eventually, the development of these systems led to an electronic control unit. It accepts data on engine load, crankshaft position, engine speed, etc. for processing. and their analysis selects the optimal ignition timing, according to the ignition map stored in the memory of the control unit computer.

Electronics thus undoubtedly offers us everything that traditional mechanics in the ignition system, with increased precision. But we know from practice that the growing number of sensors scattered throughout the car does not always guarantee maximum reliability. Whether there is a solution to such difficulties is another question. But one thing is for sure - the answer to it is known to car manufacturers themselves.

author: AUTONET.HR

Retrieved from: www.autonet.hr

Recommendation of similar texts:

Hi there, I am Mladen and I am an auto enthusiast. I started this blog years ago to help like minded people share information about latest cars, car servicing ideas, used car info, exotic cars, and auto technology. You will find helpful articles and videos on a wide variety of cars - Audi, Mercedes, Toyota, Porsche, Volvo, BMW and much more. Ping us if you have anything cool to share on latest cars or on how to make older cars more efficient, or just want to say hi!