Number and arrangement of engine cylinders - How many cylinders in the engine is optimal?

Number and arrangement of engine cylinders

How many cylinders are optimal?

The number of cylinders in car engines varies from two to 12 (or even 16), so it is logical to ask yourself how the number and arrangement of cylinders is defined

If you had the opportunity to mow the grass with a petrol mower, you must have noticed that the mower vibrates strongly. No wonder, the engine is single-cylinder, there is no flywheel but a mowing propeller and no balancing system. Vibrations are inevitable. Still, the car you drive is much quieter. It has four, maybe five, six or who knows how many cylinders.

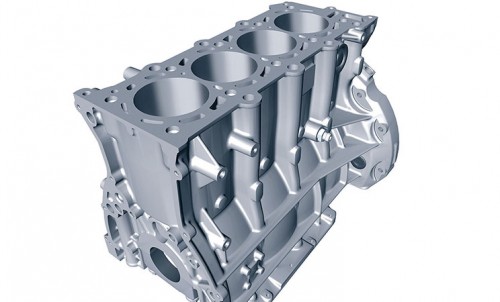

The volume of one cylinder is defined by the diameter of the cylinder and the stroke of the piston, and by adding the volumes of all cylinders we get the volume of the whole engine.

Why so much? What is their configuration? Who determined it? Why?

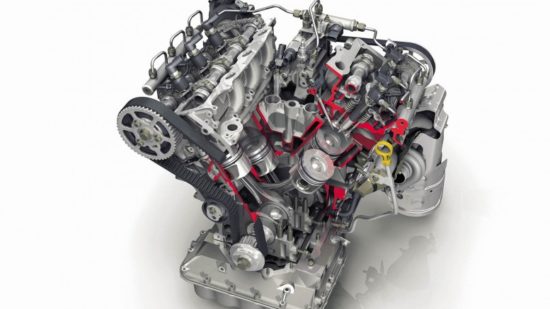

The volume of one cylinder is defined by the diameter of the cylinder and the stroke of the piston, and by adding the volumes of all cylinders we get the volume of the whole engine. It is theoretically possible that an engine for the same displacement has only one large cylinder or a larger number of smaller cylinders. Which version is better and why? Since we are (most often) talking about a four-stroke engine, the single-cylinder version will have only one stroke at every two crankshaft revolutions. Since the engine consumes power (or kinetic energy) on the other three strokes, it is necessary to accumulate it during the working stroke and release it in the other three. For this purpose, a flywheel is used whose mass is higher the smaller the number of cylinders, and in defiance of a large flywheel, the engine with only one cylinder is extremely unbalanced and works very restlessly.

The higher the number of cylinders, the more even the operation of the engine (although there are exceptions here, this fact can be taken as a rule). Also, engines with a larger number of cylinders need smaller flywheels, and the ideal balance is a 12-cylinder engine whose ignition schedule is optimal. As a rule, multi-cylinder engines are operated in the V configuration to reduce their length.

The ideal of balance is a 12-cylinder engine whose ignition timing is optimal

However, the most important factor in determining the number of cylinders is the individual volume of each cylinder, which is of course equal. When the size of the cylinder decreases, its volume decreases faster than its surface, which means that more combustion heat is lost through the larger surface of the cylinder walls, which goes to the coolant and the environment instead of helping gas expansion and "pushing" the piston. A volume of 200 cc per cylinder is considered to be the minimum for acceptable thermal and mechanical efficiency while it is desirable to have over 300 cc.

On the other hand, a very large volume of the cylinder would cause problems with combustion, because in a large space, the fuel would not burn fast enough. If the cylinder had a small diameter and a very large stroke, it would cause very large mechanical friction losses, which is again not acceptable, and today there is a regular "square" version in which the diameter and stroke of the piston are approximately the same. Due to all the above, the cylinder volume over 800 cc or over 100 mm in diameter is not recommended. For easier calculation, just the fact that a square engine with a diameter (and stroke) of 86 mm with four cylinders has exactly two liters (1.998 cc), while six such cylinders give three liters, and eight four liters. Therefore, it is no coincidence that most V10 engines have about five liters, ie that the volume of V12 engines is around six liters.

There are, of course, exceptions, especially in America where engines have larger individual volumes, but as a rule these are engines with lower rotational speeds than in Europe. This again means that engines of about one liter and less have three cylinders on a regular basis for these reasons.

A volume of 200 cc per cylinder is considered to be a minimum for acceptable thermal and mechanical efficiency while preferably over 300 cc.

What's going on in the engine?

The piston moves up, reaches GMT and returns back to the DMT and then up again. The piston rod swings from left to right, the crankshaft rotates. The piston has some mass, the piston rod accompanying it as well. The movement is constantly accelerated, ie. the piston speed is never constant. So he has some inertial force that changes in direction and amount.

This is one source of vibration from our engine starting from the mower. What if we took two equal pistons and adjusted them so that when one goes up, the other goes down? Then their inertial forces would cancel out inside the engine and it would work still, wouldn't it?

Indeed, that would calm that part of the story, but now we come back to the term four-stroke. In order for the engine to run at all, we need an expansion clock that is played every other crankshaft revolution, ie. for every 720 degrees. We want our engine to run as evenly as possible, so an even ignition gap is required.

If we have two cylinders, then the ignition clock will happen twice as often (seen at the engine level), that is. every 360 degree crankshaft. Which means both of our pistons are going up and down at the same time. Instead of one, I now have a twice as big problem. It is an example Fiat's Twin Air (otherwise shiny) twin-cylinder engine.

Well, let's add another cylinder. The ignition gap is going in the right direction, with each stroke separating the crankshaft at 240 degrees. Looking ahead, the crankshaft looks like a Mercedes star. When all forces are considered now, they are balanced. Our engine doesn't jump like crazy up and down, but it sways left and right. What's going on now?

Explosions in the cylinder swinging germs, connecting rods and crankshafts are the source of vibration

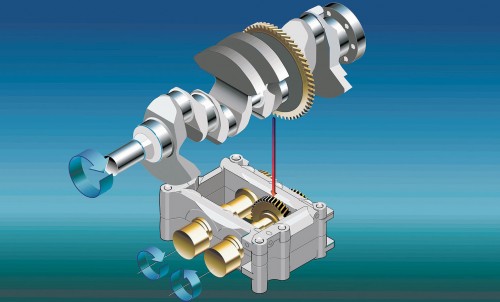

The moment of these inertial forces is not balanced. It can be aligned with a special shaft on which there will be weights that correspond in amount to the inertial forces of the pistons and that shaft must rotate in the opposite direction from the crankshaft at the same speed. Everything is fine now, but that came back is a complication. Can it be avoided?

So why not add another cylinder? Anyway, 85 percent of engines have just such a configuration. The ignition distance is now exactly 180 degrees. Two cylinders go up, two go down. Let the outer ones go up, let the inner ones go down. The inertial forces are balanced, their moment as well. Everything wonderful?

Not really. Nature has left us with another trap; when these forces are described by the sum of the order, the first term is obtained (representing the forces of the first order) and the second (about 30 percent of the order of magnitude of the second, a force of the second order acting at twice the frequency). Second-order forces are looking up at the same time, so below, our engine is no longer as nicely balanced as we thought.

And that can be solved; two shafts rotating in opposite directions twice as fast as the crankshaft will cancel it too. Such solutions are quite rare, but not nonexistent. It is almost exclusively a two-liter or larger engine that balances perfectly. But that complication with the extra shafts doesn’t look very nice and it consumes energy.

Two shafts rotating in opposite directions twice as fast as the crankshaft will cancel vibrations and balance the engine

The next step is to add two more cylinders. Regular six. That's all right. All inertial forces and moments are balanced. No wonder BMW swears in such a configuration. Still, such an engine is long. That is why they place some cylinders in the V arrangement. And now comes the crucial question; what is the angle between the cylinders?

The school says: 120 degrees ensures even ignition spacing. Well, that's too broad. That's why it's usually done in 60 degrees. Then the crankshaft is broken, but everything is in balance. If the angle is 90 degrees then the first-order forces are not balanced, so a balance shaft is added. The 8-degree V90 is a school-like example of an engine that does absolutely nothing. Force, torque, ignition spacing. The V10 requires an angle of 72 degrees (equal ignition distance), the V12 angle of 60 degrees.

There are still boxers left. With them, the angle between the cylinders is 180 degrees, but the pistons do not go in the same direction as with the V engine, but in the opposite direction. Consequence: the four-cylinder has balanced inertial forces, but no moments. At six-cylinder boxers everything is in balance.

Source: www.autopartner.com.hr

Recommendation of similar texts:

Hi there, I am Mladen and I am an auto enthusiast. I started this blog years ago to help like minded people share information about latest cars, car servicing ideas, used car info, exotic cars, and auto technology. You will find helpful articles and videos on a wide variety of cars - Audi, Mercedes, Toyota, Porsche, Volvo, BMW and much more. Ping us if you have anything cool to share on latest cars or on how to make older cars more efficient, or just want to say hi!

There are engines with 1 cylinder…