How do disc brakes work?

Disk brakes

The first experiments with disc brakes were made in the late 19th century in England. They were patented by Frederick William Lanchester in Birmingham in 1902. Unfortunately, it has taken half a century for the technology to advance sufficiently to make the discs sufficiently reliable and economically viable for mass use.

In the late XNUMXs and early XNUMXs, the British realized that disc brakes provided significantly better stopping characteristics than conventional drum brakes. Also, the disks were significantly more resistant to overheating, proved to be more reliable due to their relatively simple construction and fewer components, and we should not forget the easier adjustment.

As is the case with most new technologies, disc brakes were first used on race cars. Nowadays, discs are standard on the front wheels, while the rear ones are still commonly used drums, despite what many fans of modern technology consider them a legacy of the last century. The fact is that many cars simply do not need the wheels on the rear wheels, since during heavy braking much of the mass from the rear axle shifts to the front.

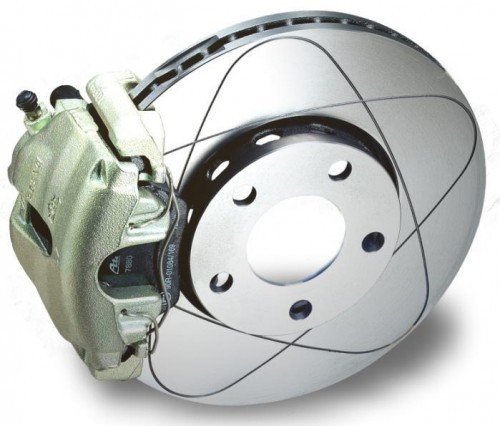

To most easily understand how disc brakes work, simply look at the brakes on the bike - the rubber-coated jaws press the rim of the wheel and slow it down. The brakes on the car also work, except that the brake calipers press on the disc located on the hub on which the wheel is mounted.

The brake discs are poured out of one piece, sometimes leaving openings or shallow surface channels to improve cooling, more effectively remove the surface layer from the brake pads (thus improving braking) and water.

Sometimes they are poured into the form of two connected disks to allow more air to circulate between them for better cooling. Such discs are mostly used in sports pedigree cars, but today there are many "civilian" vehicles on the market that are significantly faster, more powerful and incomparably heavier than race cars.

The brake calipers press the discs over the brake brakes to slow down the rotation of the wheels. On this occasion, a large amount of heat is released, which means that the material made of the tiles must be able to withstand very high temperatures. It used to be made of asbestos, but today it has been eliminated due to carcinogenicity.

The brake pads should be changed regularly to avoid damage to the brake discs and potentially significantly higher costs. Modern cars have special systems (electronic or mechanical) that alert to the deterioration of the tiles.

Types of brake pliers

The brake disc rotates with the wheel and is covered by the brake pliers that contain the brake pads. When the driver decides to decelerate or stop, he will apply the brake pedal, which will use the hydraulics to depress the brake pads against the brake disc and thus slow down the rotation of the wheel.

There are two types of brake calipers: floating and fixed. Fixed pliers can be recognized by the fact that they do not move in relation to the disk - they use one or two pairs of clips to press the tiles on both sides of the disk. Service technicians say they are significantly more complex than floating pliers.

The floating pliers are moved relative to the disk so that the piston on one side of the disk pushes the inner plate until it makes contact with the disk, after which the body of the tongs is pulled by the outer plate to the point when the outer plate also acts on the disk. At this point we have a brake disc pressed on both sides by the brake pads.

One hydraulic piston in the cylinder is the cheapest version, although up to eight pistons are used in high performance brakes.

Prepared by: Dragan Romčević

Retrieved from: www.polovniautomobili.com

Recommendation of similar texts:

Hi there, I am Mladen and I am an auto enthusiast. I started this blog years ago to help like minded people share information about latest cars, car servicing ideas, used car info, exotic cars, and auto technology. You will find helpful articles and videos on a wide variety of cars - Audi, Mercedes, Toyota, Porsche, Volvo, BMW and much more. Ping us if you have anything cool to share on latest cars or on how to make older cars more efficient, or just want to say hi!