Turbo Charger and Compressor - Part Three

Turbo charger

Problems that occur with a turbocharger

1. Too much pressure

When the air is compressed into pressurized cylinders made by a turbocharger which then compresses the piston, there is an increased risk of the mixture igniting. Auto-ignition of the mixture occurs when the air-fuel mixture is compressed over a critical point, thereby detonating the cylinder even though the spark plug did not ignite the mixture, which could damage the engine. Cars with turbochargers typically use high-octane fuels (which have higher self-ignition resistance) to avoid this problem. The problem can also be solved by reducing engine compression which of course leads to a decrease in engine power.

2. Turbo Lag

One of the most noticeable problems with turbochargers is that they run the instant you press the accelerator pedal, the engine needs to provide the right amount of gas, and then it takes a few more moments for the turbine to spin to get started, resulting in the car it suddenly gains strength just moments after depressing the accelerator pedal. One way to reduce this effect (lag = delay prim.prev.) Is to reduce the interior of moving parts, ie. reducing their weight. This allows the turbine and air compressor to spin quickly and start early with an increase in engine power.

3. Small or large turbocharger?

A surefire way to reduce the inertia of a turbine and air compressor is to make the turbocharger as small as possible. A small turbocharger will provide much faster pressure and less engine speed, but will not be able to provide enough pressure when the engine is spinning and when it needs large amounts of air to maintain the required pressure. An additional danger is that a small turbine at high engine speeds may spin too fast, which can damage it.

A large turbocharger can provide high pressure at high engine speeds, but it is heavy and inert and needs more time to accelerate its heavy turbine and air compressor.

… And their solutions

Exhaust air vent (wastegate)

Most car turbochargers have an excess air exhaust valve that allows smaller turbochargers not to spin too fast at high speeds, while at the same time reducing the lag. The excess air exhaust valve allows the exhaust gases not to pass over the turbine blades. The valve "senses" the change in pressure and if the pressure exceeds a certain limit it is an indicator that the turbine is turning too fast and then the valve discharges some of the exhaust gases so that they do not pass over the turbine, thus allowing the turbine to slow down.

Wastegate valves - to the right is factory, to the left is high performance

Stocks

Some turbochargers use better bearings instead of the fluid reservoir as a support for the turbine shaft. These, of course, are not ordinary bearings - they are super-precision bearings, and the materials they make are special alloys that can withstand the high speeds and temperatures produced by the turbine. They allow the turbine shafts to spin with less resistance than with the use of fluid instead of the lag used in most turbochargers. They also allow smaller and lighter shafts to be used, which again helps the turbocharger start faster and thus further reduce turbo lag.

Stocks

Ceramic blades on turbines

Ceramic blades on turbines are lighter than those of the steel most commonly used on turbochargers. Of course, this again allows the turbine to start faster, which again reduces lag. For example, ceramic blades are used with the IHI turbine on the Mitcubishi Lancer EVO.

Intercoolers

When the air is compressed (according to the laws of thermodynamics) it is heated, and when the air is heated it expands. So one part of the increase in turbocharger pressure is the result of heating the air before it enters the engine. To increase engine power, the goal is to increase the number of air molecules in the engine, not necessarily increase the air pressure. An intercooler is an additional component of a refrigerator-like system, except that air passes through and around the intercooler. The air that is to enter the engine passes through the intercooler and thus cools, while the outside air is blown through the intercooler by a fan. The intercooler increases the car's power by cooling the pressure air exiting the turbine before entering the engine. This means that a turbocharger operating at 0,5 bar pressure with the help of an intercooler injects cold air at 0,5 which contains far more air molecules since cooler air is denser than warmer.

Intercooler

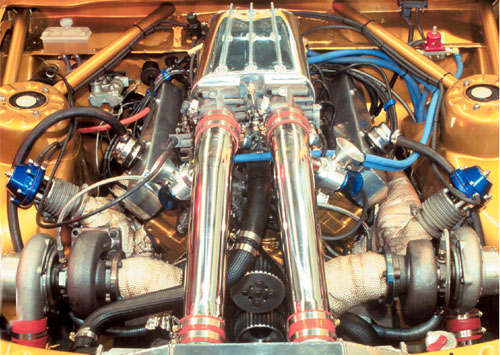

Twin Turbo - Parallel or Sequential?

The use of twin turbochargers is a question of desired efficiency and the ability to place them somewhere physically. For larger engines, say over 2,5l, it's better to use 2 smaller turbochargers instead of one big one - like Porsche did on the early 911 Turbo models. When it comes to V or boxer engine construction it is also advisable to use a twin turbo because one turbo serves one side of the engine and thus shortens the length of the turbocharger hose which reduces lag. Some engines that have a twin-turbo have such a system that exhausts gas from one turbine to another turbine, and this is the so-called "feedback" concept that provides a balanced power supply to both sides of the engine. Engines having a parallel twin turbo are engines having one turbine per side of the engine. On the other hand, the sequential twin-turbo is designed to accelerate the response of the turbine and further reduce lag. Such a system works as its name sequentially means. at low rpm, a small turbine runs and the larger one is inactive and thus achieves a rapid response at medium rpm. When the amount of exhaust gas is increased sufficiently, another turbine is activated, which further increases the pressure. The drawback of sequential twin turbines is the large amount of hose required for the system to work (the exhaust gases must reach both turbines separately as well as the outputs from both turbines must reach the intake branches of the engine) and thus have recently been abandoned technique by the manufacturer. Cars using this kind of turbine system are the Porsche 959, the third-generation Mazda RX7, the Toyota Supra and the Subaru Legasi.

Parallel twin turbo - Toyota Supre engine

Light Pressure Turbo (LPT)

For the last few years, this has been a very popular way of using turbines. Saab as a pioneer in this area first used LPT in mass production in 1992 when it launched the then new Saab 9000 2,3l Turbo Ecopower. That engine only had 170bhp, ie. 20 hp more than an identical engine without a turbocharger, and 30 hp less than a standard 2,3 Turbo engine. While other manufacturers wanted as much power or torque as possible, Saab wisely concluded that while such an engine is weaker than its competitors, with the help of a small turbine, the engine has solid torque for good acceleration but far easier to drive since it is turbo lag is virtually non-existent, and the response to throttle control is the same as with atmospheric engines. Due to a better torque curve, Saab extended the gearbox ratio, further reducing consumption and reducing it to a smaller than the same size engine.

In the past, poor driving performance and high fuel consumption prevented turbochargers from being used in cars intended for a wide range of people. In recent years, this trend has been completely different because of the demand for more space and comfort, which has led to an increase in car weight, so that performance remains at the previous level, more power is required, either by installing a larger engine or by adding a turbocharger. When price comes into play, too. the desire for the lowest possible cost of each turbine manufacturer has an undeniable advantage, and this is certainly a tendency that will be more and more pronounced in the coming years. The massive use of turbines on diesel engines over the past 15 years has brought about a great deal of innovation while reducing the price of turbines, so manufacturers have been turning to turbo engines lately. For example, the new Opel has a 2.0 Turbo engine and the 1,6 Turbo is announced. Alfa Romeo has several Turbo and Twin Turbo engines in the announcement. In addition to the 1,8 Turbo engine, the VW Group also included 2,0 Turbo in the range, etc.

We are also required to list several major turbocharger manufacturers: Garett, KKK and IHI.

Retrieved from: www.automobilizam.net

Recommendation of similar texts:

Hi there, I am Mladen and I am an auto enthusiast. I started this blog years ago to help like minded people share information about latest cars, car servicing ideas, used car info, exotic cars, and auto technology. You will find helpful articles and videos on a wide variety of cars - Audi, Mercedes, Toyota, Porsche, Volvo, BMW and much more. Ping us if you have anything cool to share on latest cars or on how to make older cars more efficient, or just want to say hi!