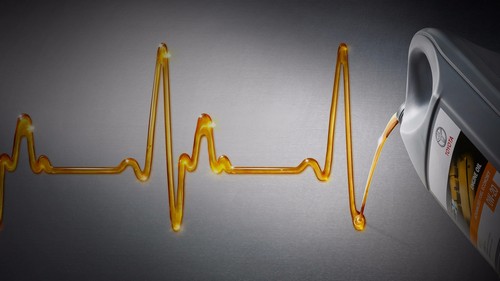

Motor lubrication as a bloodstream in humans

The task of the engine lubrication system is to cool the engine elements and remove the resulting impurities and sediments outside the engine.

Pressure oil is one of the main parameters for diagnosing engine condition. For very worn engines and high mileage engines, the pressure oil is usually lower and increases at a slower speed as the engine warms up.

It is important to check the pressure only when the engine is already hot, because the cold oil is denser, which can produce misleading results. Most vehicles do not have a pressure gauge oil in the set, so an external pressure gauge is required for diagnosis. This is a must have for every professional car workshop.

Practice shows that the quality of engine oil has a key influence on the durability of the engine. Under no circumstances should you save money by extending the mileage between oil changes. Especially when the car is mostly used in the city, the oil ages faster.

High oil parameters are required by turbocharged engines. The turbine itself is a highly thermally loaded element. For engines of this type, remember to cool the drive unit after a long drive before switching it off. Otherwise, the turbo compressor, heated to high temperatures, causes oil to burn and soot to form, which will overwhelm the rotating elements of the turbocharger. This is usually the beginning of the process of destroying the turbocharger, which often happens with turbo diesel.

The lubrication system requires no special care from you. It is enough if you change the oil and filter regularly, if the car has stopped and the engine oil has cooled, give the engine time to warm up, do not force the engine to high speeds immediately and let it cool down after a long run. These are rules whose observance extends the life of the whole engine.

Oil indicator

The oil pressure indicator on older models was only on when the pressure dropped below the minimum. However, in technically advanced vehicles, the lamp can give different messages. A topping symbol of red oil indicates a drop in oil pressure. Sometimes it is accompanied by an acoustic signal, you must immediately shut off the engine. An oil symbol that is yellow (or orange) may indicate that the oil level is too low, it is not necessary to switch off the engine immediately.

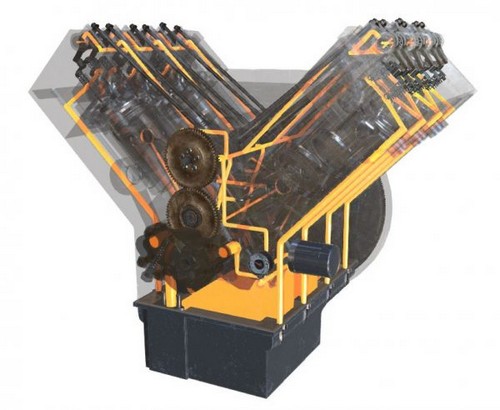

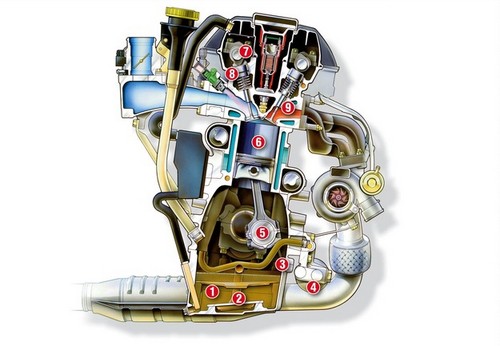

Engine Lubrication System

Engine oil is extracted from the crankcase through the so-called. sieves. The pipe goes further to the oil pump, which is started directly from the motor shaft or through gears (eg chain). There is a valve at the outlet of the oil pump that maintains the correct pressure. When the oil pressure rises with engine speed, excess oil returns to the oil pan. The pressurized oil flows through the filter and goes on to the lubricated elements. First, there are the crankshaft bearings, the cylinder liner and the cylinder head. The head lubricates elements such as camshafts, valve lifters and valve guides. Depending on the solution, the oil pressure sensor is located on the pump or closer to the head. Thus, in some models, the oil pressure lamp goes out when the starter is started and in others, just a moment after the engine is started.

Bearings

These are the elements that lie between the crankshaft and the connecting rod. Their operation is possible due to the presence of oil pressure, which does not allow direct contact of the cooperating elements. Malfunctions: loss of lubrication. They are usually preceded by a clear sound. Solution to the problem: engine overhaul.

Oil pump

Provides correct oil pressure in the lubrication system. Failures: Increasing pump clearance causes a decrease in lubrication pressure. A symptom may be an oil pressure warning light on a hot engine when idling. Solution: Usually the oil pump is completely replaced with a new one.

Oil filter

Separates dirt circulating in the lubrication system. Malfunctions: the filter gets dirty over time. It is worth noting that sometimes the filters differ slightly depending on the year of the vehicle. Solution: Strictly change the filter when changing the engine oil.

Carter oil

It is a container from which the lubrication system draws in fresh oil. Malfunctions: Typical of this element are mechanical damage resulting from an impact on an obstacle. Occasionally, there is a leak from the seal between the crankcase and the engine. The oil drain plug may be damaged. Solution: The damaged container may be welded or replaced with a new one. The leaks are removed by sealing.

Pressure sensor

This is a very important element that monitors the oil pressure in the system. Faults: A broken sensor may have a short circuit, resulting in the oil pressure indicator constantly illuminating. However, the engine with the indicator light may not be used (this could mean a serious engine failure). Solution: Replace the oil pressure sensor with a new one.

Turbine

The turbocharger is lubricated and cooled with the same oil as the entire engine. Breakdowns: Wearing the turbocharger causes oil to enter the intake and exhaust systems. Bug fix: It is usually possible to overhaul the turbocharger, and in extreme cases it needs to be replaced with a new one.

Recommendation of similar texts:

Hi there, I am Mladen and I am an auto enthusiast. I started this blog years ago to help like minded people share information about latest cars, car servicing ideas, used car info, exotic cars, and auto technology. You will find helpful articles and videos on a wide variety of cars - Audi, Mercedes, Toyota, Porsche, Volvo, BMW and much more. Ping us if you have anything cool to share on latest cars or on how to make older cars more efficient, or just want to say hi!