Transmission and Differential Oils

Transmission and Differential Oils

Gear oils for motor vehicle gears

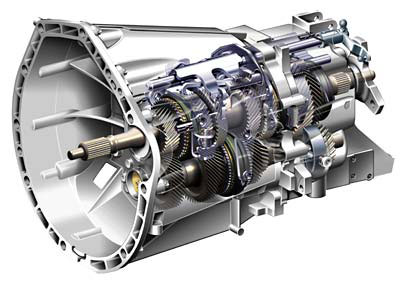

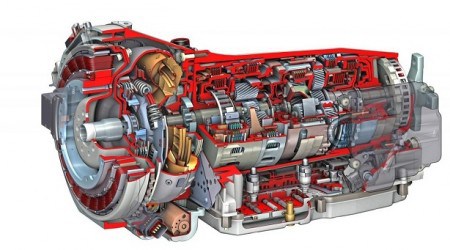

Transmission assemblies have different gears: with straight, oblique and helical teeth, hypoid or worm pairs. Depending on the type of gears and loads, these systems operate under conditions of hydrodynamic, elastohydrodynamic and mixed lubrication, which in snare and hypoid gears, under shock loads and extreme pressures, turns into boundary. These are the conditions under which the oil film is intermittently interrupted, and at the points of direct contact of the joined surfaces of the teeth the temperature rises, which can result in destructive friction and wear, and even digestion. Therefore, the recommendations and the selection of the oil are made according to the types of gears in their assemblies and the type of load. For lubrication of gears (gearboxes and differentials) of motor vehicles, a special class of oil has been developed, unlike gearboxes (gearboxes) in the industry, due to the different nature of the load, and the operating conditions differ significantly.

crossed with spiral teeth

Rack

Figure 1: Types of gear pairs

Oils for lubricating manual transmissions and differentials of motor vehicles

The task of gears, transmissions and differentials is to transfer engine power to the axles and wheels of the vehicle. In doing so, the gear teeth are exposed to extremely high pressures. The highest pressures occur when starting and stopping a vehicle. The development of motor vehicles is in the direction of increasing power and better starting, which results in the appearance of higher slip forces, ie higher operating temperatures on the gearboxes and differentials.

For lubrication of gearboxes in such harsh operating conditions, only lubricating oils produced on the basis of high quality base oils and the selected additive package can satisfy. Base oils may be mineral refiners, hydrocracked oils or synthetic hydrocarbons. The additives used in the production of these oils are: corrosion and rust additives, high pressure and wear protection additives, point-of-cure additives, oxidation protection additives, metal deactivators, anti-foam additives and friction modifiers.

In order to satisfy all the factors that increase the severity of working conditions, special EP (Extreme Pressure) additives are added to the oil, which also give different quality levels of these oils. EP additives are based on sulfur, phosphorus or chlorine. At elevated temperatures, which are the result of high pressures and impact loads, these additives chemically react with the metal surface, forming appropriate compounds and films that protect the metal surface from wear and damage to the gear teeth. It should be borne in mind that EP additives can cause corrosion on non-ferrous metal parts, so their amount in the oil must be balanced so that they can create a protective film without causing corrosion on metal surfaces. The task of gear oils: reduction of friction and wear, cooling, removal of metal particles and impurities from contact zones and corrosion protection.

Viscosity data and data on the quality of the oil and its performance are required for the selection of the oil. As with engine oils, SAE viscous oil grades for gearboxes and differentials refer solely to viscosity and do not determine the quality level of the oil.

The classification of oils for gearboxes and differentials of motor vehicles by viscosity (SAE J 306 of 1998) is shown in Table 36. According to the viscosity range multigrade gearbox and differential oils can be divided into two categories:

- SAE 80W-90 i narrow range multigrade oils

- multigrade oils with wide viscosity SAE 75W-90, SAE 85W-140

Widespread viscosity oils must contain a higher percentage of viscosity enhancer additives to meet the prescribed viscosity requirements. For this reason, ASTM introduced a 20-hour shear stability test CEC L-45-T-93, which assesses the ability of an oil to retain the strength of an oil film and to protect parts in contact with each other, ie to keep the oils in gradation.

There is no relationship between SAE viscous grades of engine oils and gearbox and differential oils but they can be compared in terms of application:

- SAE 75W corresponds to the viscosity of SAE 10W engine oils

- SAE 80W corresponds to the viscosity of SAE 15W, SAE 20W, SAE 20W-20 engine oils

- SAE 85W corresponds to the viscosity of SAE 30W engine oils

- SAE 90 corresponds to the viscosity of SAE 40W and SAE 50 engine oils

- SAE 140 corresponds to the viscosity of SAE 60W engine oils

Viscosity has a significant effect on the load carrying capacity, on the ease of gear shifting and on possible fuel savings. Recently used multigrade oils have made a compromise between the required viscosity at high temperatures, the easy shifting of speeds and the small internal friction when starting the vehicle at low temperatures.

Table 1: Classification of gear oils by viscosity SAE J 306, 1998

|

SAE

viscous gradation

|

Maximum temperature (0C) at which the Brookfield viscosity is 150 mPasa

|

Limit values of kinematic viscosity (mm2/ s) at 100 0Cb

min. max.

|

|

|

70w

|

- 55

|

4,1

|

-

|

|

75w

|

- 40

|

4,1

|

-

|

|

80w

|

- 26

|

7,0

|

-

|

|

85w

|

- 12

|

11,0

|

-

|

|

80

|

-

|

7,0

|

11,0

|

|

85

|

-

|

11,0

|

13,5

|

|

90

|

-

|

13,5

|

24,0

|

|

140

|

-

|

24,0

|

41

|

|

250

|

-

|

41

|

-

|

|

a - ASTM D 2983, Brookfield b - ASTM D 445

|

|||

Table 2: Classification of transmission oils by performance - SAE J 308, 1989

|

API service

|

Oil type or specification

|

% EP additives

|

Possibility of application

|

|

API GL-1

|

Oil without EP additives, may contain oxidation and corrosion inhibitors and depressants

|

-

|

Spiral - bevel and worm gears for particularly light load conditions. Manual transmissions operating under low load conditions.

|

|

API GL-2

|

Oils containing all additives such as GL1 and anti-wear additives

|

-

|

Worm gears for heavier working conditions. For gearboxes where oils without EP additives are required and API GL-1 is not satisfactory.

|

|

API GL-3

|

Oils containing all additives like GL-2 and EP medium efficiency

|

2,5

|

Spiral-toothed gears for moderate to harsh load conditions. They are not intended for hypoid gears.

|

|

API GL-4

|

Oils containing high efficiency EP additives

MIL-L-2105; MAN 341; MB 235.1

|

3,8

|

With helical-conical and hypoid gears without shock loads. They are widely used in passenger and truck gearboxes. They can also be used for low load differentials.

|

|

API GL-5

|

Oils containing the same EP additive as GL-4 only in higher concentration.

MIL-L-2105 B; MIL-L-2105 C

MIL-L-2105 D; MAN 342; MB 235.0

|

6,5

|

With hypoid gears for heavy duty shock loads. For lubricating differentials and rear axles of vehicles. They can also be used for gearboxes that require GL-5.

|

|

API GL-6

(terminated)

|

Oils containing the same EP additive as GL-5 only in higher concentration.

FORD WSW-M 2C-105 A

|

9,0

|

With hypoid gears operating in conditions of particularly high speeds and impact loads, long shaft spacing and large tooth clearance. The use of these oils has been significantly reduced.

|

|

MT-1 API

|

Oils containing EP additives and additives to improve thermal stability.

MIL-PRF-2105 E.

|

For non-synchronized manual gearboxes for buses and heavy trucks. For EATON and FULLER gearboxes.

|

|

|

MT-2 API

|

Similar to the MT-1 API specification

|

For manual non-synchronized light truck transmissions.

|

Table 3: Overview of MIL-L specifications

|

MIL-L-2105

|

Fits: API GL-4; MAN 341; MB 235.1. Hypoid gears that work without shock loads. Gearboxes for passenger and commercial vehicles.

|

|

MIL-L-2105B

|

Fits API GL-5; MAN 342; MB 235.0. Monograde oil. Hypoid gears that work with shock loads. Passenger and freight vehicle differentials.

|

|

MIL-L-2105C

|

Fits API GL-5; MAN 342; MB 235.0. Multigrade oil. Hypoid gears that work with shock loads. Passenger and freight vehicle differentials.

|

|

MIL-L-2105D

|

API GL-5 Enhanced Version; MAN 342; MB 235.0.

|

|

MIL-L-2105E

|

Fits the MT-1 API. Non-synchronized manual gearboxes for buses and heavy trucks exposed to high operating temperatures.

|

Table 4: Motor vehicle manufacturer's requirements for gearbox oil

|

Specification

|

A request

|

Oil change interval (km)

|

|

MB 235.1

|

SAE 80W;

API GL-4

|

90.000 * 350.000**

|

|

MB 235.5

|

SAE 80W; 80W90; 85W140; SAE 90; SAE 140;

API GL-4

|

90.000 * 350.000**

|

|

Volvo 97305

|

SAE 75W; 80W; 90; 85W140; 80W140;

API GL-4

|

120.000

|

|

Volvo 97307

|

SAE 75W80 / 85W

API GL-4

|

180.000

|

|

MAN 341N

|

SAE 80W; 80W90; 85W90; 90

API GL-4

|

80.000

|

|

MAN 341 ML

|

SAE 80W; 80W90; 85W90; 90

API GL-4

|

160.000

|

|

MAN 341 FIG

|

SAE 75W80; 80W90

API GL-4

|

300.000-400.000

|

|

Iveco

|

SAE 80W

GL-3 / GL-4 API

|

120.000

|

|

ZF TE ML 02

|

SAE 80W

API GL-4

|

80.000

|

|

ZF TE ML 01/02

|

SAE 75W85W

API GL-4

|

300.000

|

|

Note: * without flexible service system (without FSS) ** with flexible service system (with FSS)

|

||

Table 5: Requirements of motor vehicle manufacturers in relation to differential oil

|

Specification

|

A request

|

Oil change interval (km)

|

|

MB 235.0

|

SAE 90; 85W90; 85W140

API GL-5

|

90.000 * 350.000**

|

|

MB 235.3

|

SAE 90; 85W90 (hypoid for passenger vehicles)

API GL-5

|

90.000 * 350.000**

|

|

MB 235.4

|

SAE 75W; 85W (gearbox oil for differentials)

API GL-5

|

90.000 * 350.000**

|

|

MB 235.6

|

SAE 80W90; 85W90; SAE 90;

API GL-5

|

90.000 * 350.000**

|

|

MB 235.7

|

SAE 85W90 (universal hypoid for passenger train.)

API GL-5

|

90.000 * 350.000**

|

|

MB 235.8

|

SAE 75W90 - Synthetic oil

API GL-5

|

350.000

|

|

Volvo 97310

|

SAE 75W; 80W; 90; 85W140; 80W140

API GL-5

|

120.000

|

|

Volvo 97312

|

SAE 75W90

API GL-5

|

180.000

|

|

MAN 342N

|

SAE 80W; 80W90; 85W90; 90

API GL-5

|

80.000

|

|

MAN 342 ML

|

SAE 80W; 80W90; 85W90; 90

API GL-5

|

160.000

|

|

MAN 342 FIG

|

SAE 75W80; 80W90

API GL-5

|

300.000-400.000

|

|

Iveco

|

SAE 90; SAE 85W140

API GL-5

|

120.000

|

|

ZF TE ML 05

|

SAE 90

API GL-5

|

80.000

|

|

Note: * without flexible service system (without FSS) ** with flexible service system (with FSS)

|

||

FSS - serviceable systems include the processing of parameters that are registered with the built-in encoders: operating modes, load, number of starts, data on fresh oil and changes. These parameters are collected in a database for processing diagnostics of the condition of oils and parts of motor vehicles and decisions are made on the necessary intervention.

Table 6: MAN manufacturer specifications for gearbox and differential oils

|

The class

oil

|

SAE viscosity gradations

|

Use

|

Assembly

|

Oil change

|

Remark

|

|

N

|

80W, 90

80W-90,

85W-90

|

Wide application

|

Gearbox, rear wheel bearing housing and differential

|

up to 90.000 km or once a year

|

Mineral oil, conventional formulations

|

|

ML

|

80W, 90

80W-90,

85W-90

|

Long distance vehicles

|

Gearbox, rear wheel bearing housing and differential,

Total Driveline

|

up to 160.000 km or once a year

|

Mineral oil, special additive technology

|

|

TL

|

75W-80

|

Long distance vehicles

|

Transmission

|

up to 320.000 km or 1 per year

|

Semi-synthetic oil

|

|

SL

|

75W-80

|

Long distance vehicles

|

Transmission

|

up to 500.000 km or 1 per year

|

Synthetic special formulation oil

|

|

75W-90

|

Differential

|

up to 320.000 km or 1 per year

|

|||

|

75W-90

|

Total Driveline

|

up to 160.000 km or 1 per year

|

Figure 2: Transaxle and differential layout

Table 7: MB specifications for gear oils for differentials (hypoid oils)

|

MB list

|

SAE gradation

|

Use

|

Remark

|

|

MB 235.0

|

90, 85W90

|

Hypoid gears of passenger and freight vehicles, planetary gears, non-synchronization. MB dividers and partly bellows. management

|

Mineral oils

|

|

MB 235.6

|

90, 80W90, 85W90

|

Hypoid and planetary laptops of lorries and non-synchronized MB distributors

|

Mineral oils

|

|

MB 235.7

|

85W90

|

Universal oil for hypoid gears of passenger vehicles

|

Mineral oils

|

|

MB 235.8

|

75W90

|

Universal oil for hypoid gears of trucks

|

Synthetic oil

|

|

MB 235.9

|

75W90

|

AG 4 Hypoid Gear Oils, Allowed for VW AG-4 Automatic Gear

|

Synthetic oil

|

Table 8: MB specifications for gearbox gear oils

|

MB list

|

SAE gradation

|

Use

|

Remark

|

|

MB 235.1

|

80, 80W, 90 80W85,85W90

|

Gearboxes with steel / molybdenum synchronization in MB and ZF manifolds

|

Mineral oils

|

|

MB 235.4

|

75W-85

|

For UNIMOG gearboxes UG 3/65. Meets the specifications of ZF TE-ML 02 and ZF TE-ML 01.

|

Synthetic oil

|

|

MB 235.5

|

80W, 80W-85

|

Oils for MB and ZF gearboxes with steel / molybdenum synchronization and for MB and ZF manifolds

|

Mineral oils with a new package. additives

|

|

MB 235.10

|

75W-80

|

For G16 / G28 type trucks, for SG 150/180 (A-Class) passenger vehicles and for all type 717.4 gearboxes of 7340241

|

Semi-synthetic oil

|

|

MB 235.11

|

30, 40

|

For all MB and ZF gearboxes with steel / molybdenum synchronization with and without oil cooler, and MB distributors

|

Engine oil in tropical gearboxes

|

Transmission and Differential Oil Quality Requirements:

- Passenger cars are characterized by high speed and trucks and buses with high torque. These oils must satisfy both operating conditions.

- Anti-wear and tear-resistant property for extreme pressures and shock loads.

- Good viscous-temperature characteristics, which means easy transfer at cold start and sufficient oil film strength at high operating temperatures.

- Good oxidation and thermal stability, which ensures long oil use. In modern vehicles, the oil fill temperature can be up to 140 0C.

- Corrosion protection especially in the presence of water.

- Compatible with gaskets.

- Anti-foam property.

In the vehicle's propulsion system, gearboxes should allow optimum matching between engine speed and wheel speed. This is achieved through gearboxes and differentials. In addition, in the case of longitudinally mounted motors, the energy flow must be diverted by 90o. The compensation gear compensates for the difference in speed when cornering. When choosing oil, the vehicle manufacturer's recommendations regarding viscous SAE grades and the corresponding API GL categories should be followed in the first place. For all models "SOUTH“SAE 80W-90 API GL-3 is recommended. In these models, the integrated gearbox-differential includes non-ferrous metal parts, so API GL-4 or API GL-5 hypoid oils are not recommended.

Synchronized gearboxes: Due to the synchronous rings, the use of highly additive API GL-5 oils is not allowed, but API GL-4 is exclusively recommended. Some manufacturers of synchronized transmissions require API GL-3 and even GL-1, and some even prescribe oils for automatic transmissions and even engine oils, which of course should be respected.

Non-synchronous gearboxes are relatively insensitive to EP additives, so oils of both specifications -API GL-4 or API GL-5 can be used.

Differentials: As a pair of hypodermic gears can withstand very high loads over a very small touch surface, almost a point, it is imperative that lubricants are recommended for hypoid oils that meet API GL-5 specification.

For lamellar (plywood) differentials special requirements are set in relation to friction. For these types of differentials, special oils are produced that are marked LS (Limited slip).

It has been used since 1990 modified CVT gearbox - Continnously Variable Transmission due to increased economy especially in city driving. Experience shows that vehicles with CVT gearboxes have up to 17% less fuel consumption than vehicles with hydrodynamic gearboxes, but also set the most stringent shear oil resistance requirements.

Lubricating oils for automatic transmissions of motor vehicles - ATF

Automatic Transmission Fluid (ATF) oils are relatively low-viscosity oils (approximately comparable to SAE 75W) with a high viscosity index and a flow point below –400C. They have high oxidation stability, good viscous temperature and low temperature characteristics, provide good corrosion protection and excellent foaming and air release properties. They must also satisfy the requirement of constant friction coefficients.

They consist of base oils and additives. Base oils can be conventional raffinate, hydrocracked oil or synthetic hydrocarbon. Additives are used: to protect against corrosion and rust, to improve viscosity, friction coefficient modifiers, to protect against high pressures and wear, to improve the flow point, oxidation protection additives, to prevent foam and metal deactivators.

The gearbox oil needs to handle more gear in the gearbox. In addition to the lubrication function of the planetary gears, which form the main assembly of automatic transmissions, ATF oil performs the function of hydraulic oil, which allows for easy gear shifting in the complex hydraulic system, as well as smooth operation of the hydraulic torque converter, which plays the role of a coupling connecting the input shaft to the planetary system. gears. With all of these tasks, the automatic gearbox oil must maintain an adequate coefficient of friction.

Automatic transmission oils are used to lubricate automatic transmissions, power steering and torque converters. They are required: good lubrication and cooling to allow the transmission of power to the gear flanges or torque converters, adequate friction coefficient for optimum gear change, wear and corrosion protection, seal compatibility, high oxidation stability and foaming resistance.

Oxidation and thermal stability - The new constructions of automatic transmissions are smaller and lighter constructions, and such are required to transmit higher torques, which results in increased thermal load per unit volume of oil. In addition, there is a constant demand for extended oil filling life. These reasons require oxidationally very stable oils for automatic transmissions.

ATF oils must have good oxidation stability at temperatures up to 1500C. At these elevated temperatures and with the presence of air, there is an accelerated process of oil oxidation and many unintended consequences such as:

- the acids formed, as products of intense oxidation, have a corrosive effect on the bushes and other structural materials as well as on the sealing materials and the composition of the coupling plates

- changing friction characteristics causes excessive slip of the couplings

- sludge as a product of oxidation can block hydraulically controlled valves and other narrow channels for fluid passage

- resins and varnishes, as oxidation products, can cause the control valves to become stuck and transmission failures

- the viscosity of the oil increases which leads to a decrease in automatic transmission functionality

The oxidation stability of automatic transmission oils is determined by changing the acid number according to the DEXRON and MERCON specifications, or by changing the kinematic viscosity according to the ZF specification. The requirement for increased oxidation stability indicates the use of quality base oils, that is, the transition from API Group I to API Group II, III, or IV base oils.

Low-temperature properties - Automatic gearboxes are sophisticated electronic control systems that require adequate rheological properties even at the lowest temperatures. The low temperature properties of the oils are expressed as the maximum permissible value of dynamic viscosity at -400C as measured by a Brookfield viscometer. Increasingly stringent requirements for better low-temperature properties require the use of higher quality base oils than API Group I. The use of viscosity index enhancers must be limited.

Shear stability - Due to the mechanical loads to which the oils for automatic transmissions are exposed, the chains of molecules, especially the higher molecular weight, break, and there is a permanent drop in the viscosity of the oil. These problems are solved by using shear-stable viscosity modifiers while using quality base oils.

Anti-wear properties - Oils for automatic transmissions must have good anti-wear properties that are necessary for the durability of assemblies and parts of automatic transmissions, and thus the extension of the oil change interval is ensured. A Vickers vane pump is used to evaluate the anti-wear properties of the oil. The results are expressed by the loss of mass of the vanes and rings of the pump after the end of the test.

Friction properties - Friction properties of oil are very important for reliable and smooth operation of automatic transmissions. The values of the oil friction coefficients must be within precisely defined permissible limits because the engagement of the gear is carried out by means of lamellar couplings and belt brakes lined with friction linings. It is this feature that makes the basic difference between individual oils for automatic transmissions, ie the specifications of individual manufacturers. Further development of ATF oil goes in the direction of the development of additives, especially friction modifiers that provide the optimal coefficient of friction while keeping it within the prescribed limits.

Viscous gradations for ATF fluids are not prescribed (SAE, ISO VG), but are an integral part of the given specification. Performance is defined by the specifications of General Motors and Ford and is shown in Tables 9 and 10. Most other manufacturers (MAN, Mercedes Benz, Renk, Voith, ZF) have accepted one or another specification, although some prescribe additional tests. , to ensure compatibility with their automatic transmissions.

The General Motors specification includes the requirements of automatic gearbox oils in terms of: high oxidation stability, high ignition points, foaming resistance, compatibility with seals, proper friction coefficient, ie balanced friction and lubrication.

Ford introduced the M 1959C 2-G specification in 33. The new Ford specification is labeled Ford Mercon. This new specification, and also the two previous ones (M 2C 166-H and M 2C 138-CJ), require oil containing friction modifiers, which satisfies with respect to the coefficient of friction, GM-Dexron requirements.

In automatic transmissions for passenger cars and commercial vehicles today, with few exceptions, Dexron II D / E or Dexron III is used. When using an ATF according to the Ford specification SQM-2C 9007 A (M 2C-33G), caution should be exercised as this product has completely different friction characteristics than all other ATFs and should therefore not be mixed with other automatic transmission oils. However, ATF fluids of specification M 2C - 33 G (G-oils) are very rarely used today.

Dexron IID specification oil is often recommended for heavy duty power steering, turbo couplings and torque converters, and sometimes for manual gearboxes as required by the manufacturer. Ford MERCON and General Motors DEXRON IIE / III are very similar so automatic transmissions known manufacturers meet the requirements of both specifications.

Motor vehicle manufacturers recommend replacing automatic transmission oil at 40.000 km. For some new gearbox models: ZF 5HP18 or ZF 5HP30 and ATF Dexron III oil filling is permanent.

Automatic transmission oil can be used for a variety of hydraulic systems in industry, shipping and transportation, for hydraulic vehicle control systems, for screw compressors, and for heavy-duty hydraulic gears.

Table 9: GENERAL MOTORS specification for ATF oils

|

Tip A

|

The first specification for automatic transmissions, prescribed in 1949.

|

|

Type A Suffiks A

(TASA)

|

Модели 1957г. Outdated specification but still in use. Suffix A indicates that the oxidizing properties have been improved.

|

|

DEXRON B

|

Модели 1967г.

|

|

DEXRON II

|

Модели 1973г. The most used specification. Includes special requirements for low static coefficient of friction, for high oxidation stability and good corrosion protection in a humid chamber.

|

|

DEXRON II D

|

Модели 1981г.

|

|

DEXRON II E

|

Модели 1991г. It includes, in addition to laboratory testing of physicochemical characteristics, special requirements for low static coefficient of friction, requirements for high oxidation stability, ignition and burning point, foaming properties, good corrosion protection in a wet chamber, and compatibility requirements with gaskets.

|

|

DEXRON III

|

Модели 1994г. A specification that includes improved all characteristics compared to the previous ones, primarily higher ignition and burning temperatures and a lesser tendency to foam.

|

Table 10: FORD specifications for ATF oils

|

SQM-2C9007A (M2 C33-G)

|

This oil has completely different friction characteristics than all other ATFs and should not therefore be mixed with other oils. Модели 1967г.

|

|

SQM-2C9010A (M2 C138-CJ)

|

Модели 1973г.

|

|

ESPM-2C166-H (M2 C166-H)

|

Модели 1981г.

|

|

THANK YOU

|

Модели 1987г. The specification specifically emphasizes wear, antifoam, anti-corrosion compatibility, seal compatibility and ignition temperature.

|

|

THANK YOU

|

Models 1993 Revision of the previous MERCON. Requires stricter control of volatility, color and all other properties from the previous specification. V100 ≥6,8 mm2/ s; V-20≤1500 mPa.s; V-40 ≤9000 mPa.s; T. of ignition ≥1770C; Noack = 10%

|

|

MERCON V

|

Модели 1995г. Specification requiring more stringent wear, friction and oxidation tests.

|

Table 11: Equipment manufacturer specifications

|

Specification

|

Type of oil

|

|

Color

|

Manufacturer of automatic transmissions for commercial vehicles. Prescribes two types of ATF oil:

|

|

Voith

|

Manufacturer of automatic transmissions for buses, commercial vehicles, locomotives.

|

|

Allison C-4

|

Oil for heavy-duty transmissions used in commercial vehicles, agricultural and construction machinery.

|

|

Caterpillar TO-4

|

Monograde oils of grades SAE 10W, 30 and 40. In addition to the requirements for the FZG test and the pass test at the Vickers pump, special emphasis is placed on the requirement to meet the VC70 Friction test and the compatibility test on seals.

|

Table 12: Mercedes Benz specifications for ATF oils

|

Specification

|

Type of oil

|

|

MB 236.1

|

Quality level of DEXRON IID and III, Allison C-4, Voith. For MB automatic transmissions of passenger, off-road and commercial vehicles.

|

|

MB 236.2

|

ATF Type A Suffix A, Allison C-4. For manual transmissions of passenger and off-road vehicles.

|

|

MB 236.3

|

ATF for power steering

|

|

MB 236.5

|

Transmission Fluid for Allison Gearboxes. Allison C4 quality level.

|

|

MB 236.6

|

ATF DEXRON IID, Allison C-4. For MB automatic transmissions of passenger, off-road and commercial vehicles. For split-drive hydraulic controls (4 Matic) and some manual gearboxes for passenger vehicles.

|

|

MB 236.7

|

ATF Quality Level DEXRON IID, Allison C-4

|

|

MB 236.8

|

ATF Quality Level DEXRON IIE, Allison C4, ZF TE ML14, Voith G 607 / G 1363. For arctic areas.

|

|

MB 236.9

|

ATF quality level DEXRON III, ZF TE ML14, Voith G 607. For passenger and off-road vehicles.

|

|

MB 236.10

|

ATF for MB automatic transmissions with or without built-in electronically controlled shutter in torque converter

|

|

MB 236.11

|

Oil formulations according to special requirements. ZF 4HP 20 and VW AG4

|

Table 13: MAN specifications for ATF oils

|

Specification

|

Type of oil

|

|

MAN 339 Type A

|

For Renk Doromat gearboxes. Quality Level: GM Type A Suffix A.

|

|

MAN 339 Type D

|

For ZF synchronized gearboxes, ZF and Voith automatic transmissions and Allison gearboxes. Applies to hydraulic steering, tipper hydraulics, axle control and suspension hydraulics. Quality level: GM Dexron IID.

|

|

MAN 339 Type D

(ZF Ecomat 120.000 km)

|

For ZF synchronized gearboxes, ZF and Voith automatic transmissions and Allison gearboxes. Applies to hydraulic steering, tipper hydraulics, axle control and suspension hydraulics. Quality level: GM Dexron IIE.

|

|

MAN 339 Type F

|

For ZF synchronized gearboxes, ZF and Voith automatic transmissions and Allison gearboxes. Applies to hydraulic steering, tipper hydraulics, axle control and suspension hydraulics. Quality level: GM Dexron III.

|

|

MAN 339 Type F

(ZF Ecomat 120.000 km)

|

For synchronized transmissions, ZF and Voith automatic transmissions, Allison transmissions capable of operating at temperatures below -450C. Applies to hydraulic steering, tipper hydraulics, axle control and suspension hydraulics. Quality level: GM Dexron III.

|

Table 14: ZF (Zahnradfabrik Friedrichshafen) specifications

|

ZF list

|

Description

|

Quality requirements

|

Viscous gradations

|

|

TE-ML01

|

Manual synchronous transmissions for commercial vehicles

|

API GL-4, MIL-L-2105

API GL-5, MIL-L-2105D

|

SAE 80W / 80W-85W

SAE 80W-90/85W90/90

|

|

CD / CE / CF / SF / SG API

MIL-L2104C / D / E, MIL-L46152C / D / E

|

SAE 30/40

|

||

|

TE-ML 02A

|

Manual and automatic gearboxes for trucks and buses

|

API GL-4, MIL-L-2105, mineral

|

SAE80W/80W85W/80W90

|

|

TE-ML 02B

|

Mineral or synthetic gear oils in accordance with ZFN13019

|

SAE80W/80W85W/80W90

/75W80/75W85/75W90

|

|

|

TE-ML 02C

|

Engine oils in accordance with ZFN 13020

|

SAE 30/40

|

|

|

TE-ML 02D

|

Semi-synthetic and synthetic oils in accordance with ZFN13010 in Intarder gearboxes

|

SAE 75W80 / 75W85 / 75W90

|

|

|

TE-ML 02E

|

Synthetic gear oil with Intarder

|

SAE 75W80

|

|

|

TE-ML 02F

|

ATF Dexron II or III in agreement. with ZFN 13015

|

Special formulation

|

|

|

TE-ML 02G

|

Mineral oil according to ZFB 864 for first filling. Not for laptops with Intarder

|

SAE 75W

|

|

|

TE-ML 02 p.m.

|

Mineral oil compliant with Iveco requirements, exclusively for ZF gearboxes with Intarder

|

SAE 80W-90

|

|

|

TE-ML 02K

|

Synthetic base hydraulic oil for hydraulic actuator as per special requirement of ZF

|

SAE 70W-75

|

|

|

TE-ML 02L

|

Synthetic oil for extended replacement intervals in Intarder laptops

|

SAE 75W-85

|

|

|

TE-ML03

|

Torque converters, hydraulic couplings for heavy goods vehicles and machinery (cranes and other vehicles)

|

API CD / CE / CF / SF / SG, MIL-L-2104C / D / E

MIL-L-46152C / D / E Caterpillar TO-4

John Deere JDM J20C

|

SAE 10W/10W30/10W40/

15W40 / 20W20

SAE 10W / SAE 30

SAE 10W30

|

|

DEXRON IID / III;

MERCON M

Caterpillar TO-4;

John Deere JDM J20C

|

SAE 10W / 30

SAE 10W30

|

||

|

TE-ML 04A

|

Ship transmission systems

|

Mono Engine Oils - API CD / CE / CF-4 / CF / SG / SH / SJ or ACEA A / B / E

|

SAE 30 (SAE 40 for warmer climates)

|

|

TE-ML 04B

|

Mono engine oils according to ZFN13024

|

SAE 30 (SAE 40)

|

|

|

TE-ML 04C

|

Multigrade engine oils according to ZFN13024

|

SAE 10W40 / 15W40

|

|

|

TE-ML 04D

|

Buckle oil clip

|

||

|

TE-ML 05A

|

Axles for heavy goods vehicles and off-road construction vehicles. Off-road vehicles.

|

Mineral and semi-synthetic gear oils in accordance with ZFN 13011

|

SAE 75W90 / 75W140 / 80W90 / 80W140 / 85W90 85W140 / 90

|

|

TE-ML 05B

|

Synthetic gear. oils in accordance with ZFN 13011

|

SAE 75W90 / 75W140

|

|

|

TE-ML 05C

|

Mineral gear oils in accordance with ZFN 13011 with «limited slip» additives

|

SAE 75W90/75W140/ 80W90/ 80W140/85W90/ 85W140 / 90

|

|

|

TE-ML 05D

|

Synthetic gear oils in accordance with ZFN 13011 with «limited slip» additives

|

SAE 75W90 / 75W140

|

|

|

TE-ML 05E

|

UTTO oil for tractors and construction machinery.

|

SAE 20W-40, SAE 80W-140

|

|

|

TE-ML 05F

|

UTTO oil for tractors and construction machinery

|

||

|

TE-ML 05G

|

Specially developed oil for construction machinery shafts with extended replacement intervals

|

||

|

TE-ML 06A

|

Transmission and hydraulic systems of tractors

|

Engine Oils - API Category A / B / E CD / CE / CF4 / CF / SF / SG / SH / SJ or ACEA

|

SAE 20W20

|

|

TE-ML 06B

|

STOU in accordance with ZFN 13022, brake test

|

SAE 10W30 / 10W40 / 15W30 / 15W40 / 20W40

|

|

|

TE-ML 06C

|

STOU in accordance with ZFN 13022

|

SAE 10W30 / 10W40 / 15W30 / 15W40 / 20W40

|

|

|

TE-ML 07A

|

Hydrostatic, mechanical and electrical drive system

|

Gear oils in accordance with ZFN 13016

|

SAE 80W85 / 80W90 / 80W140 / 85W90 / 85W140 / 90

|

|

TE-ML 07B

|

STOU in accordance with ZFN 13022

|

SAE 10W30 / 10W40 / 15W30 / 15W40 / 20W40

|

|

|

TE-ML 07C

|

Lubricating oils in accordance with ZFN 13012

|

SAE 10W30 / 10W40 / 15W30 / 15W40

|

|

|

TE-ML 07D

|

Engine Oils - API CD / CE / CF-4 / CF / SF / SG / SH / SJ or ACEA Category A / B / E

|

SAE 20W20/30/5W30/5W40 /10W30/10W40/15W30/ 15W40

|

|

|

TE-ML 08A

|

Control systems for passengers, commercial. and heavy cargo. vehicles

|

Gear oils

API GL-4 MIL-L-2105

|

SAE 75W80/75W85/75W90 80W/80W85/80W90

|

|

TE-ML 09A

|

Control systems and oil pumps for passenger cars, commercial. and heavy goods vehicles

|

Control system with ZF vane pump - ATF

|

|

|

TE-ML 09B

|

Other versions - ATF

|

||

|

TE-ML10

|

Transmission System for Passengers and Commercial. vehicles

|

API CD / CE / CF / SF / SG, MIL-L-2104C / D / E, MIL-L-46152C / D / E

|

SAE 20W20 (SAE 10W and SAE 30 depending on ambient temperature)

|

|

TE-ML11

|

Manual and Auto Transmissions for Passenger Vehicles

|

S5-28 and S5-31; EssoATF

S5-31 and S5-39; Esso Gear Oils 304

|

|

|

TE-ML 12A

|

Differentials and rear axles for passenger cars, commercial vehicles, buses…

|

Mineral and semi-synthetic gear oils by ZFN13016

|

SAE75W90/75W140/80W90 80W140/85W90/85W140/90

|

|

TE-ML 12B

|

Synthetic gear oils. according to ZFN 13016

|

SAE 75W90 / 75W140

|

|

|

TE-ML 12C

|

Mineral gear oil ZFN13016 with limited slip

|

SAE75W90/75W140/80W90 80W140/85W90/85W140/90

|

|

|

TE-ML 12D

|

Synthetic oils ZFN13016 with limited slip

|

SAE 75W90 / 75W140

|

|

|

TE-ML 12E

|

Mineral or half-synth. gear oil. especially for portal axles of low-floor buses

|

SAE75W90/75W140/80W90 80W140/85W90/85W140/90

|

|

|

TE-ML13

|

ZF assemblies in special vehicles

|

||

|

TE-ML 14A

|

ECOMAT automatic transmission for commercial vehicles

|

Mineral ATF according to ZFN 13015. Replacement at 1000 rpm or 20.000 - 30.000km

|

|

|

TE-ML 14B

|

Semi-synthetic ATF according to ZFN 13015. Replacement at 2000 rpm or 45.000 - 60.000km

|

||

|

TE-ML 14C

|

Synthetic ATF according to ZFN 13015. Replacement at 3000 rpm or 90.000 - 120.000km

|

||

|

TE-ML 14E

|

Synthetic ATF. Replacement at 4000 rpm or 120.000 - 150.000km or once every three years.

|

||

|

TE-ML15

|

Special Vehicle Braking System

|

||

|

TE-ML 16L

|

ECOMAT automatic transmission in rail vehicles

|

Substitution at 45.000 km. Mineral

|

|

|

TE-ML 16M

|

Replacement at 90.000 km. Mineral and semi-synthetic

|

||

|

TE-ML 16N

|

Replacement at 120.000 km. Synthetic

|

||

|

TE-ML 17C

|

Transmission fork lift truck with slanting and planetary gears

|

||

Source: www.nisotec.eu

Recommendation of similar texts:

Hi there, I am Mladen and I am an auto enthusiast. I started this blog years ago to help like minded people share information about latest cars, car servicing ideas, used car info, exotic cars, and auto technology. You will find helpful articles and videos on a wide variety of cars - Audi, Mercedes, Toyota, Porsche, Volvo, BMW and much more. Ping us if you have anything cool to share on latest cars or on how to make older cars more efficient, or just want to say hi!