Piezo injector - Faults - Common rail system

Piezo injector

The moving elements of the nozzles are lubricated with fuel, which is injected into the combustion chamber, and not with engine oil. As a result, the durability of the piezo injector depends on the quality and purity of the fuel.

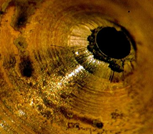

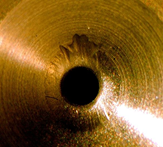

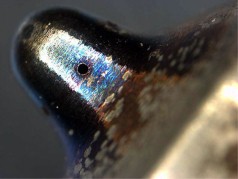

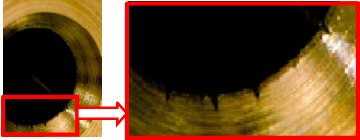

Damage to the valve seat due to the operation of fuel that has dirt inside.

Examples of injector valve seat damage.

Images represent damage to the injector valve seat by exploitation. This can be seen as corrosion damage. They are the result of dirty fuel and tight closing of the valve. Little leakage caused high-pressure fuel flow on closed valve seats causing permanent damage to the injector.

A

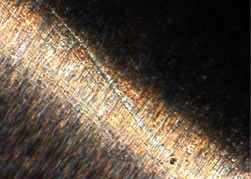

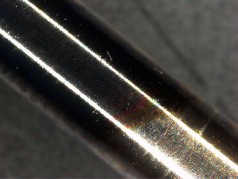

Examples of needle tip damage. A- lack of lubrication within the top of the valve (oil diluted with gasoline), exploitation B - engine with the use of vegetable oil purchased in the store

A

C

Other damage to injector elements, A - dirt in fuel, B - corrosion of elements, C - sludge in fuel

piezo injector

An example of a piezo injector leak

The most common reasons for leaking piezo injectors are:

- Using the wrong type of fuel

- Dirty fuel

- Poor quality fuel filter

- Chips from fuel system elements, especially from high pressure fuel pumps

- Water in fuel

- Poor fuel quality.

A

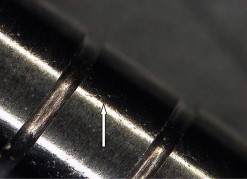

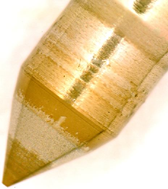

Damage to the Piezoelectric Injector PISTON: a) a recess, b) a groove with a visible dirt footprint

A

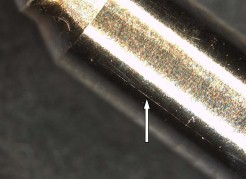

Damage to the piezoelectric needle injector: a) longitudinal scratches, b) needle cracks

A

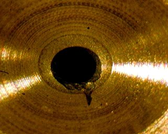

Damaged piezoelectric injector: a) appearance after disassembly with motorm

b) Appearance after clearing - visible damage caused by high temperatures

Thermally colored piezoelectric injector needles

Piezo injectors are prone to failures. Some of the reasons for these failures are high mileage, contaminated fuel, especially fuel that has water contamination or a dirty and clogged fuel filter.

Piezo injectors can be damaged when removed from the cylinder head. Sometimes it takes a lot of force to apply to pull the injector out of the cylinder head. (combustion products or rust build up on the injectors). This force can damage the sensitive crystals in the injector.

Visually, the injector will not look different, but the damage will mean that it cannot be repaired.

Common rail injector servicing

What happens after 100 km of common rail system exploitation?

The most common problems are:

- Hard or heavy ignition

- Loss of power or engine shutdown during acceleration or loading

- Black smoke and increased fuel consumption

- Restless idling

- The jitter and “click” of the engine in mid-range

- Crankcase oil level increase due to "leak"

- Engine twitch

Recommendation of similar texts:

Hi there, I am Mladen and I am an auto enthusiast. I started this blog years ago to help like minded people share information about latest cars, car servicing ideas, used car info, exotic cars, and auto technology. You will find helpful articles and videos on a wide variety of cars - Audi, Mercedes, Toyota, Porsche, Volvo, BMW and much more. Ping us if you have anything cool to share on latest cars or on how to make older cars more efficient, or just want to say hi!