Clutch - Clutch problems

Clutch

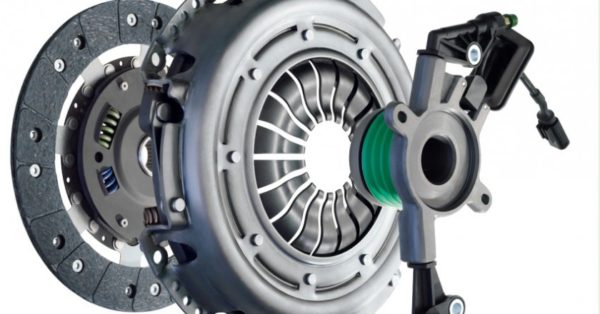

Modern clutches are designed to withstand over 100.000km-150.000km. It depends on the driving style. Unless the clutch is taken care of, it can take less than 50.000km. So longevity depends most on materials and driving style.

Slipping the slats

Vehicles that are constantly overloaded are more likely to have clutch problems. It is often the case that the slats slip, even on relatively new clutches. The engine spins the flywheel, but the force exerted by the thrust bearing on the blade is not sufficient, because too much resistance makes it difficult to start the wheels.

The wear of the blade

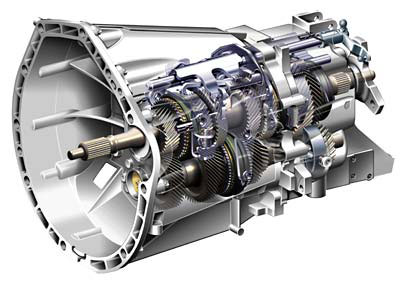

The most common problem with the clutch is that the friction material on the blade is consumed. This material is very similar to that of brake pads and brake linings. After a while, this material will wear out. When enough material is exhausted, the blade will start to slip and transfer less power from the engine to the transmission. Eventually, the car will completely stop, as the blade will slip completely.

The blade only consumes as it and the flywheel rotate at different speeds, that is, when it slides relative to the flywheel. When fully connected, they rotate at the same speed and there is no wear on the blade. The life of the blade is significantly reduced for drivers who:

- They "sign" the tires as they go

- they like their slats to slip

- they keep their foot on the clutch pedal while driving

- keep the car on an uphill clutch

Other clutch failures

Sometimes the clutch problem is not slipping. If the blade does not separate (fully) from the flywheel when we remove the leg from the clutch pedal, the shaft entering the transmission will continue to rotate. Then we are in a situation where we cannot accelerate, and / or characteristic contraction sounds occur.

The most common reasons for gluing lamellae are:

- Broken or stretched clutch cable - the cable must be properly tightened to be able to pull and push properly.

- Clutch cylinder leaks or malfunctions - if clutch oil leaks somewhere, it will prevent it from charging enough pressure. It can be manifested by the failure of the clutch pedal.

- Air in the pipes with clutch oil - if air enters the system, there is a problem, because it is compressible, unlike oil. Then sufficient pressure cannot be achieved in the hydraulic lines. It can be manifested by the failure of the clutch pedal.

- Poorly adjusted clutch - not enough force is transmitted when we remove the foot from the clutch pedal.

- Badly fitted clutch parts - some clutch parts that can be found on the market are not compatible (appropriate).

Another clutch problem may be the hard clutch pedal. There may be several causes for this. The most common problem is in a fork or lever that transfers force from the pedal to the clutch. Also, the clutch can be rigid due to leaks in the hydraulic system or clogging.

The thrust bearing (druk stock) can also malfunction. He pulls the thrust plate over the fan, thus releasing the blade. If, when you take your foot off the clutch, you hear a croaking rolling noise, you probably have a problem with the thrust bearing.

The grip spring in the clutch basket may also be a problem. It can lose strength over time and become elastic. She is no longer capable of performing her function.

Clutch life, as we said before, depends most on the driving style. When replacing one of the clutch parts, be sure to change the entire clutch set, as it is very likely that the other parts are not in good condition. In that case, you would have to go to the master again after a short time because of the same problem, and this operation is not cheap.

Retrieved from: www.auto-delovi.org

Recommendation of similar texts:

Hi there, I am Mladen and I am an auto enthusiast. I started this blog years ago to help like minded people share information about latest cars, car servicing ideas, used car info, exotic cars, and auto technology. You will find helpful articles and videos on a wide variety of cars - Audi, Mercedes, Toyota, Porsche, Volvo, BMW and much more. Ping us if you have anything cool to share on latest cars or on how to make older cars more efficient, or just want to say hi!