Starter - Starter repair - operation procedure

Anlaser - working principle and repair

Starter general-historical development

German-language starter, English-language starter motor or translated into Serbian-electric starter, as its name implies, is an electric motor used to start petrol or diesel motorboat. This is a classic one-stroke brush motor.

The first electric starter was patented in 1899 in America under the name "auto starter" while the first usable electric starter was made again in America in 1911 in DELCO, and the first serial use of the electric starter was in the 1912 Cadillac model.

The most interesting thing about this starter was that, after starting the engine, it served as an alternator ie. he was producing electricity while the engine was running. This principle has only recently been re-applied in the modern auto industry by integrating starters and power generators into the flywheel

Construction

The power of electric starters is measured in kilowatts in modern engines: in smaller petrols it is usually about 0.8 kW, in larger gasoline 1-1.5 kW and in diesel about 1.5 to over 2 kW for diesel engines of larger dimensions.

By a simple calculation in which the power is equal to the product of the connected voltage of 12V and the current in amperes that this el. the motor consumes (P = UxI) we come to a current value of about 70 amps for the smallest electric starters up to 200 amps for the electric starters of larger diesels. If we take into account that the voltage drops to around 9-10 V during "verglanja", the stated current values increase by about 20 percent.

From this it is clear that without a proper battery, there is no good starting of the engine. Considering these values, it is clear that the electric starter is very warm during operation, so it is not advisable to "run" for a long time, especially if the engine cannot start for some reason.

By design itself, the starter is not designed for extended operation at once - it has no additional cooling or classic ball bearings.

When we look at the starter itself we notice that it consists of two parts:

- most of it is just a body of a strong electric motor in which the stator windings, rotor with collector, brushes and so-called. A "bendix" consisting of a sliding bearing and a gear that sits on the flywheel.

- a smaller part called "automatic" and which is a strong electromagnet by construction, and has a dual function - by releasing current through the electromagnet, it pulls a lever that is connected to a sliding bearing that pushes the starter gear forward to connect with the flywheel gear. At the same time, the switch in the "automaton" itself, which turns on the starter, is turned on.

The switch in the automaton is because large values of the current flowing from the starter would simply "burn" the ignition switch with the key when the starter would directly switch on.

Disassembly and repair.

The electric starter is usually attached to the front or rear of the engine with three screws to the gearbox housing, so it must first be removed by unscrewing these screws. Of course, before that, we remove the battery terminals and unscrew the thicker plus wire and unhook the thinner plus wire - both red, from the launcher itself.

We will show the principle of reparation on the example of an electric starter with a power of 0.8 kW from Fiat Una 1.0 from 1993

After the starter is removed, we will first unscrew the machine itself - we'll see why.

First, unscrew the contact on the underside of the machine that goes into the starter and on the front side a couple of screws with which it is attached to the starter housing, and when removing the machine you should be careful because there is a spring under which the machine can fly out.

The machine itself has no repair options other than possibly cleaning the oxidized switch contacts from sparking when turned on

Removing the slot machine, we notice a plug of an electromagnet connected to a lever that drives the "bendix".

Now we can disassemble the electric starter itself - it usually has 2 or three long screws that extend the entire length of its body.

After that we unscrew any screws that hold the brushes on the underside.

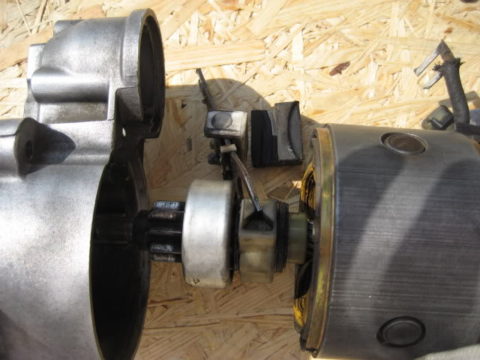

Now we can disassemble the electric starter into 3 parts - the front part, the middle part with the stator windings and the rear part where the brushes sit - there are 2 or 4 of them.

Now we can see why we removed the machine in the first place - it is easier to remove the rotor from the case with the "bendix" and the lever that connects it to the electromagnet of the machine.

Most often, the starter consumes brushes that make it no longer rotatable. The price of new brushes is around 300-450 dinars and the replacement procedure involves soldering.

As we can see, the rotor shaft does not have ball bearings on either side but sliding surfaces or "pixels" that can be changed if they are worn out by simply breaking out of the bearing.

The starter is cleaned from the inside of dust and oil and re-assembled and grease all the sliding surfaces with grease.

When everything is assembled, we can test the operation and correctness.

We connect a thick wire to the remaining free contact secured by a nut that goes to the plus of the battery. With another thicker wire, connect the minus battery and secure it to the screw on the anlaser housing. We secure the anlaser well and connect the plus battery with the other thin wire and a small clamp located on the machine just below the nut to which we connected the plus. The anlaser has to push the bendix forward and spin.

Bendix in the rear position at rest.

Bendix in the forward position, when engaging the anlaser in the actuator, the anlaser gear is connected to the flywheel gear at that moment.

Retrieved from: www.fiatisti.hr

Recommendation of similar texts:

Hi there, I am Mladen and I am an auto enthusiast. I started this blog years ago to help like minded people share information about latest cars, car servicing ideas, used car info, exotic cars, and auto technology. You will find helpful articles and videos on a wide variety of cars - Audi, Mercedes, Toyota, Porsche, Volvo, BMW and much more. Ping us if you have anything cool to share on latest cars or on how to make older cars more efficient, or just want to say hi!